| Menu |

| Homepage |

| NEW & REVISED BOOK! |

| Personal intro |

| Philosophy |

| Intro technics |

| FAQ |

| Exhaust systems |

| Exhaust overview |

| E-type |

| XJ Saloon S1,2,3 |

| XJ40 (AJ6&V12)/X300 |

| XJS |

| XK8/XJ8 |

| TT exhaust explained |

| The Jaguar V12 |

| V12 Performance |

| Stretching the V12 |

| E-type EFI conversion |

| D Jetronic |

| Lucas EFI |

| Vacuum advance |

| Ignition systems |

| V12 throttle linkage |

| Article: V12 Engine |

| V12 Archives |

| The Jaguar AJ6 |

| AJ6 Performance |

| 3.6 Richness |

| AJ6 fault codes |

| AJ6 Archives |

| The Jaguar XK |

| XK Performance |

| Article: XK Engine |

| Article: 4.2 EFI |

| The Jaguar V8 |

| AJ6 Superchargers |

| Superchargers |

| Supercharging article |

| Suspension & Brakes |

| ECU repairs |

| Miscellaneous bits |

| Glossary |

| Prices & ordering |

aj6engineering@ntlworld.com

Updated August 2016

Visitors:

73531510

|

|

Some History.

Let us start by dispelling the belief still held by a few people that Jaguar just adapted a Ford designed V8 to create their new power unit. The truth is actually the reverse. Jaguar designed the engine in its entirety, it is manufactured in the UK, and a simplified variant is shipped over to the US where Lincoln install it in their LS model!

Jaguar's design team started with a clean sheet of paper for this new V8 engine. Nothing carried over from previous engines and the aim clearly was to produce a class leading power unit with few compromises. In most respects they achieved success and were able to devise remedies for the inevitable weaknesses that emerged with time.

So wide ranging was the research to determine the best engine format to carry Jaguar into the 21st century that the program included building and testing a number of advanced two-stroke engines. Most impressive was a 3.2 litre V6, lean burn, supercharged, two-stroke using the Orbital air-assisted injection process. It produced 350 b.h.p. but emissions and durability proved to be hurdles that were too difficult to overcome. Although a fairly conventional V8 was soon perceived as being the best solution, details like the number of valves to use were resolved in a series of single cylinder prototypes, echoing the V12 program 30 years or so before. Most modern engines use the four valve layout but as befits a project aiming for the best solution, Jaguar's engineers also considered alternative arrangements like the five valve configuration used so successfully by Yamaha on their high performance motor cycle engines. No real advantage could be found that way so progress continued with a more conventional four valve layout.

A very efficient and compact combustion chamber was achieved by closing up the angle between the valves from the 47 degrees of the AJ6 and AJ16 engines to a more ideal 28 degrees, accepting the slight drawback that the head bolts were situated right under the camshafts so the heads could not be totally pre-assembled. An incidental advantage of the narrower valve angle is that it helps to keep the cylinder heads compact, so minimising the weight and package size of the complete power unit.

Special attention was devoted to the valve train to keep masses as low as possible, valve stems for example being just 5 mm in diameter. This brings advantages in three respects: firstly, there is a measurable improvement in fuel economy due to reduced friction losses; secondly, it is easier to reduce mechanical noise thereby improving refinement; finally, the mechanical stresses in the valve train are reduced. The latter point is particularly relevant but to understand why a short digression is necessary.

Purpose designed four valve V8 racing engines use a single plane crankshaft (like an in-line four cylinder) to obtain evenly spaced firing impulses along each bank to allow for optimum exhaust tuning, the downside being that the engine shakes laterally because of unbalanced forces. Even with a regular firing order such engines are notorious for timing gear problems associated with severe instantaneous torque reversals, which at different times have caused much trouble in four valve V8s from such illustrious names as Coventry Climax, Repco, Cosworth and Ilmor.

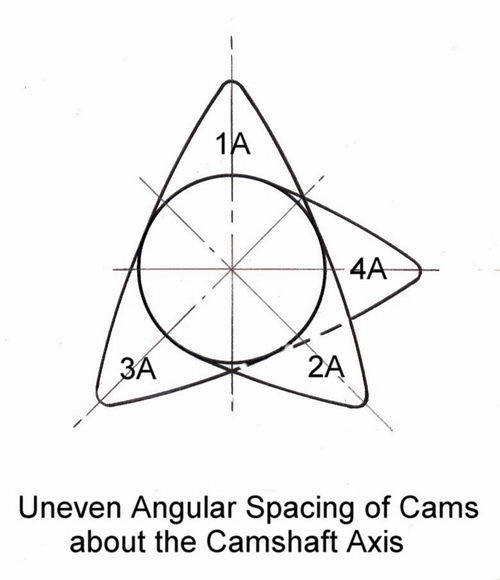

Production V8 engines almost always use a two plane crankshaft (four crank throws disposed at 90 degree intervals) which provides good balance but an uneven firing order along each bank. Because of this a four cam production V8 inevitably has the cams asymmetrically phased around the axis of each camshaft as shown in the diagram. This gives rise to irregular loads on the drive between the crankshaft and the cams and between the two camshafts on each head.

It is perhaps then not surprising that on the Jaguar V8 the tensioners on the secondary camshaft chains in particular have developed a reputation for being troublesome. In fact it may not be that there is any weakness in the tensioners themselves, rather that at certain critical speeds heavy torque reversals on the chain can produce higher than expected stab loads, a condition which can probably be exacerbated by some usage patterns. It is perhaps interesting that the later 4.2 V8 uses more rugged morse internal tooth primary chains and that when BMW introduced a similar V8 (four valve, twin OHC, Nikasil bores, sintered fracture split con-rods) in 1992 they used duplex chains throughout. Whilst Jaguar's design team, in choosing a single link chain drive, did specify that it should be rated for heavy duty, one wonders if there have been any regrets that space wasn't made to use a duplex chain rather than relying on the lightweight valve gear to let them get away with the narrower option?

Of course, all engines have weaknesses that only become apparent with time and the engineering of the Jaguar V8 is not without many positive attributes. The combination of quite large valves and cam profiles of modest duration, allied, in the case of the naturally aspirated 4 litre, to a variable timing mechanism controlling the inlet cams, results in an engine with a particularly wide spread of torque.

The early variable timing device was a two state system - either advanced or retarded over a range of 30 degrees (at the crankshaft). Retarding the inlet cam eliminated overlap so improving idle and drive quality at very low speeds and light loads. It also meant the inlet valve closed later thereby improving power at higher speeds. In the mid-speed, part to high load range, the cam was advanced giving early inlet closing to boost torque, the extra overlap then also providing a degree of 'internal EGR' to reduce NOx emissions. Later engines use a more advanced system that optimises the cam phasing within a much wider range of, incredibly, 48 degrees.

With the benefit of hindsight the decision to use Nikasil plated cylinder bores instead of conventional liners might be judged a bad mistake, but it is one that was understandable and which caught BMW off-guard as well. The Nikasil process had been used for years on motorcycle engines and is in common use for F1 and other racing engines so it is hardly unproven technology. At the time BMW's exceptionally tight control of oil on the bores was thought to be a factor in their troubles, which would not apply elsewhere. In truth, instances of failure of the Nikasil coating appear to have been induced by poor fuel quality in certain markets allied to short journey usage, and engines running on low sulphur fuel would be most unlikely to suffer the problem. Jaguar resolved service failures in an honourable fashion but eventually decided to abandon Nikasil and revert to conventional cast iron liners (from VIN 42776 XK8, 878718 XJ8). The advantages of light weight and close running clearances were sadly lost. Ironically the fuels which caused the problem have now virtually disappeared from the market.

The size increase to 4.2 litres was obtained by increasing the stroke - always a favoured approach at Jaguar - necessitating the crankpin journals to be reduced in diameter to maintain the same block height.

The supercharged V8 is an impressive performer yet flow through the intercoolers is a little constricted and the Eaton roots supercharger is not very efficient, so it could have been even better. For example, a more efficient screw type of supercharger would provide an immediate gain of around 40 b.h.p. and would make possible quite a lot more than that. Anyone interested in a more detailed explanation of why might care to read the feature about supercharging technicalities found elsewhere on this website.

Performance Enhancements.

1. Air Filter.

The starting point for upgrading most induction systems is at the air filter and this is true for the Jaguar V8. Replacing the original paper filter with a high quality low loss filter gains approximately 6 b.h.p. over standard. The JR filter that we supply is identical to the well known K & N type - only the colour is different - and is washable at service so does not need to be replaced. Surely a bargain!

2. The Exhaust System and the V8 Sound - Tasteful not Raucous.

The original system has quite a severe restriction due to the shape of the pipes at the point where they rise to pass over the rear drive-shafts. The sequence of silencers adds further restriction which saps power at the higher engine speeds. Strangely Jaguar have silenced the engine to the point where it is almost too quiet for a high performance car and the undoubtedly evocative note of the V8 is muted to the point where it is all but lost. If any engine note was ever intended to be heard it must be that of the V8 engine.

We like to think we have created the system that Jaguar would have produced if they did not have to cater for people who do not know or care about the differences between a V8 and a flat four. It recovers the power loss and subtly releases the lovely V8 sound, yet not to the extent that it becomes obtrusive and spoils the refinement of the car.

What Else?

Nothing we can talk about at the moment - but we have things in development for both naturally aspirated and supercharged V8 engines which will become available in the next few months………..

Email aj6engineering@ntlworld.com, Tel/Fax:- 0044 (0)1625 573556