| Menu |

| Homepage |

| NEW & REVISED BOOK! |

| Philosophy |

| Intro technics |

| FAQ |

| Exhaust systems |

| Exhaust overview |

| E-type |

| XJ Saloon S1,2,3 |

| XJ40 (AJ6&V12)/X300 |

| XJS |

| XK8/XJ8 |

| TT exhaust explained |

| The Jaguar V12 |

| V12 Performance |

| Stretching the V12 |

| E-type EFI conversion |

| D Jetronic |

| Lucas EFI |

| Vacuum advance |

| Ignition systems |

| V12 throttle linkage |

| Article: V12 Engine |

| V12 Archives |

| The Jaguar AJ6 |

| AJ6 Performance |

| 3.6 Richness |

| AJ6 fault codes |

| AJ6 Archives |

| The Jaguar XK |

| XK Performance |

| Article: XK Engine |

| Article: 4.2 EFI |

| The Jaguar V8 |

| V8 Performance |

| AJ6 Superchargers |

| Superchargers |

| Supercharging article |

| Suspension & Brakes |

| ECU repairs |

| Miscellaneous bits |

| Glossary |

| Prices & ordering |

aj6engineering@ntlworld.com

Updated August 2016

Visitors:

73531517

|

|

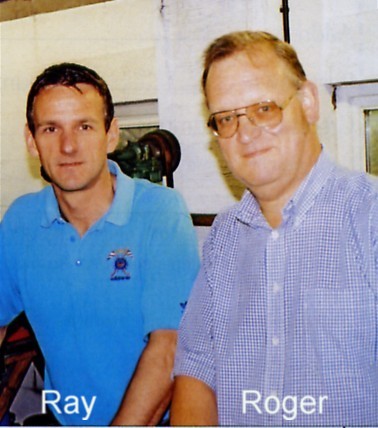

AJ6 Engineering is a small business run by two partners, Roger Bywater and Ray Timmins, who have worked together since 1980, originally servicing and repairing Jaguars before deciding to concentrate on performance development and associated electronics. Roger Bywater has accumulated 30 years of continuous involvement with the Jaguar V12 engine having worked as a Senior Development Engineer at Jaguar Cars in the 1970s in the Experimental Department on fuel injection, exhaust emission control and engine development.

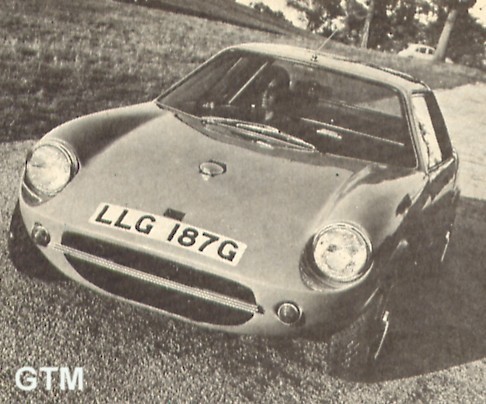

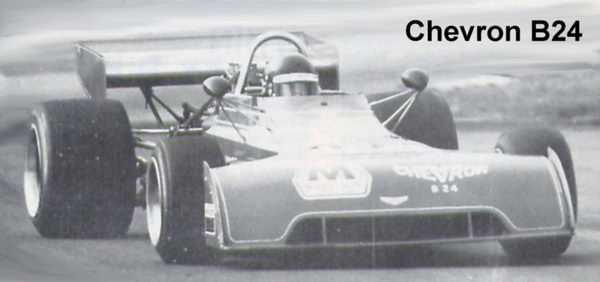

Prior to joining Jaguar Roger had been involved in racing and high performance cars in various ways, being responsible for all the original drawings for the GTM mid-engined sports car (still in production more than 30 years later) and then the very successful Chevron B24 F5000 race car.

Ray Timmins has a motor cycle racing background and might be described as the essential steadying influence needed when ideas must be turned into reliable, quality, products. The exceptional level of knowledge and experience within AJ6 Engineering is amply demonstrated by the in-depth technical features about the V12 and XK engines written by Roger Bywater for Jaguar World magazine and contributions elsewhere including the Internet. In 1987 the name AJ6 Engineering was adopted following an intensive development program to increase the performance of the AJ6 engine taking advantage of its lighter weight and modern design compared to the older Jaguar engines. Test bed work showed the value of careful development of the induction system as the most cost effective route to improved performance. Extra breathing capacity liberated more power as one might expect but more importantly, detail changes to the induction tracts made substantial mid-range torque gains possible. The fruits of this work is seen in the range of conversions now offered for all Jaguar fuel injected engines - XK, V12, AJ6 and latterly the Jaguar V8.

AJ6 Engineering did a lot of pioneering with large bore cylinder blocks for AJ6 (99 mm for 4.3 and 4.7 litres) and V12 (98 mm for 6.3 to 8 litres) engines in the 1980s but after the 1992 recession, concluded that the market for such expensive products was too limited to be viable. Since those days we have concentrated on more cost effective products that can be easily fitted and used anywhere in the world.

If there is one respect in which AJ6 Engineering is very different from its competitors, it is in the depth of knowledge of electronic systems and their application to engines and of emission control technology. Over the years a substantial part of the business has been, and still is, the testing, repair and modification of fuel injection electronic control units (ECUs). In fact a lot of this work is for other performance specialists, and not just for Jaguars but for other engines - particularly the Rover V8.

The connection to the ROVER V8 brought about a subsidiary operation, AJ6 Superchargers in Yeovil, which evolved from a company which had previously manufactured the Sprintex Supercharger. Run by one-time Dragster ace Dennis Priddle this is where all our Plus Torque manifold machining is performed and also is agent for the outstanding OPCON Autorotor supercharger from Sweden. So efficient is the OPCON that the humble ROVER V8 can be made to exceed the much lauded and tremendous output of Jaguar's recent supercharged V8, of much more modern design but encumbered as it is with the less effective Eaton supercharger which has gained popularity only because of its ready availability and low price.

Email aj6engineering@ntlworld.com, Tel/Fax:- 0044 (0)1625 573556