| Menu |

| Homepage |

| NEW & REVISED BOOK! |

| Personal intro |

| Philosophy |

| Intro technics |

| FAQ |

| Exhaust systems |

| Exhaust overview |

| E-type |

| XJ Saloon S1,2,3 |

| XJ40 (AJ6&V12)/X300 |

| XJS |

| XK8/XJ8 |

| TT exhaust explained |

| The Jaguar V12 |

| V12 Performance |

| Stretching the V12 |

| E-type EFI conversion |

| D Jetronic |

| Lucas EFI |

| Vacuum advance |

| Ignition systems |

| V12 throttle linkage |

| Article: V12 Engine |

| V12 Archives |

| The Jaguar AJ6 |

| 3.6 Richness |

| AJ6 fault codes |

| AJ6 Archives |

| The Jaguar XK |

| XK Performance |

| Article: XK Engine |

| Article: 4.2 EFI |

| The Jaguar V8 |

| V8 Performance |

| AJ6 Superchargers |

| Superchargers |

| Supercharging article |

| Suspension & Brakes |

| ECU repairs |

| Miscellaneous bits |

| Glossary |

| Prices & ordering |

aj6engineering@ntlworld.com

Updated August 2016

Visitors:

73575610

|

|

The AJ6 engine can be thought of as almost a hybrid, owing much to both the old XK twin cam and the later V12. It actually started out as a four valve conversion based on an updated version of the XK cylinder block but ended up as a completely fresh design using the V12 bore spacing, making possible fitment of the HE type of cylinder head to create the 2.9 to meet a perceived economy market. The direct connection to the XK was therefore broken and attention moved to use of modern techniques and materials.

Despite being cast in aluminium the AJ6 cylinder block is extremely stiff and rugged, having been designed with the possibility in mind that there might be a diesel version at some future date. This same unfulfilled requirement was the reason for the almost square bore/stroke ratio, which of course became considerably under-square for the long stroke 4 litre and must also have influenced the decision to spread the valves at a relatively wide angle of 47 degrees.

Much thought was given at the time to dispensing with conventional iron lined cylinders and using either the Nikasil process of plated cylinder bores or casting in a hypereutectic, high-silicon, alloy treated to produce a hard wearing surface. Considering the relatively high sulphur content of fuels at the time, and subsequent related problems with other engines using Nikasil, it is perhaps fortuitous that more conventional shrink fit, centrifugally cast, iron liners were decided upon instead.

The AJ6 engine was the first Jaguar production engine to use the four valves per cylinder layout that is now regarded as being the best way to achieve high efficiencies of both combustion and gas flow. The Jaguar design team had a lot of four valve experience progressing from the victorious Coventry Climax F1 V8, the Lotus 2 litre (also used in the Jensen Healey) and various four valve V12 and 6 cylinder experimental prototypes.

It is known that the ideal included angle between the valves for the four valve layout should not exceed about 30 degrees and most racing engines are designed to be less than that. However such a narrow valve angle means the camshafts are likely to fall almost exactly over the axes of the head bolts, so to ease assembly mass produced four valve engines sometimes use wider splayed valves than the ideal. The angle between the valves of the AJ6 engine is 47 degrees which leaves room to bring the head bolts up just inside the camshafts and through the camshaft bearings, making them readily accessible but at a price of complicating any repair work. The relatively long stroke tends to alleviate any compromise of combustion efficiency from the deeper combustion chamber and combined with very efficient porting results in an engine with very good all round performance.

History has shown the AJ6 engine to be a very reliable power unit and it responds well to breathing improvements to the induction and exhaust systems in much the same way as the older V12 and XK engines.

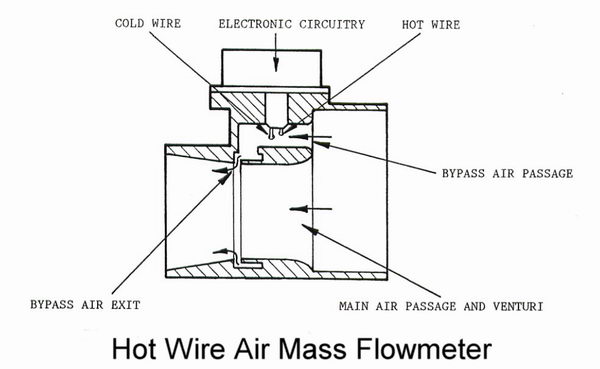

1: The first obstacle to be overcome when trying to get more performance from all but the early examples of the AJ6 engine family is the restriction to air flow caused by the "hot wire" airflow meter (diagram). The main flow through this takes place via a 55 mm venturi - not much bigger than just one of the three 2 inch S.U. carbs used by the old 6 cylinder E type engine - with a very small by-pass containing a heated wire. This generates a voltage output in proportion to air mass flow from which the ECU deduces the fueling and ignition timing requirements. Contrary to popular belief these devices are very reliable and any problems are usually associated with the connector plug.

By carefully machining the venturi to a larger diameter we found that, for the same level of restriction, airflow could be increased by 16%, sufficient for some respectable performance gains in company with other modifications. The airflow meter circuitry is then calibrated on a special airflow bench so that the ECU is able to provide the appropriate amount of fuel for all conditions although an overall trim (not for idle fuel) adjustment is provided for close matching to a individual engine should this be necessary.

This HIGH CAPACITY AIRFLOW METER added to a low loss air filter and minor changes to the filter box, forms our PLUS-FLOW CONVERSION which provides about 20 b.h.p. extra from a standard engine.

2: The throttle of the 4 litre engine can be bored out from 71 mm to 75 mm diameter to obtain a 12% increase of area. We make the new throttle disc with correct angled geometry to suit. Really this is only worthwhile for race engines where the extra flow capacity at the top of the speed range can be valuable. However the 3.2 litre AJ6 engine can benefit by having its smaller 2.5" (63.5 mm) diameter throttle assembly swapped for the 4.0 litre equivalent.

3: Having improved the flow of air into the system the next stage is to refine the inlet manifold and make it work more effectively by adding bell-mouthed extensions to the individual tracts to create stronger harmonic resonance (ram effect) with which to force more air into each cylinder.

The resulting HIGH TORQUE MANIFOLD can be added to our PLUS-FLOW CONVERSION described earlier (or similarly appropriate changes for the early XJS 3.6) to become our PLUS TORQUE CONVERSION which lifts peak torque by 13% and gains about 35 b.h.p over standard.

The maximum power gain is incidental and usually goes hand in hand with any torque gain but this conversion is really about mid-range pulling power for practical use in everyday conditions. Applicable to any AJ6 engine of 3.2, 3.6 or 4.0 litres, the gains vary slightly according to engine size.

The photograph shows how the inlet manifold is cut open to obtain access to install the bell-mouth extensions for our high torque version. It is all welded back together afterwards using slightly bulged castings to replace the cut out pieces so that there is better clearance internally around the bell-mouths.

4: Exhaust system improvements start with replacing the more restrictive of the silencers with our preformed ready-to-fit SILENCER SUBSTITUTE PIPES replacing the first silencers under the rear seat area for a power gain of about 15 b.h.p. and a slightly raised but pleasant exhaust tone.

A LARGE BORE EXHAUST SYSTEM is the next option but because it only gives a small gain over the Silencer Substitute Pipes we only recommended it if the complete system is in need of renewal.

As a moderately priced but effective performance option we recommend our TT EXTRACTOR SYSTEM which augments mid-range torque by about 12%. This replaces the downpipes with a tuned length twin pipe system merging at the back of the transmission which then divides again to each side of the car to join up with the original rear section. Standard and Large Bore (for those who require slightly more power at the top of the speed range) rear sections are available in addition if required although it must be said that some people would find the Large Bore rear section a bit too noisy for daily use. Versions available for XJ-S and XJ40.

5: The AJ6 engine is generally very reliable so good secondhand units are readily available. It is therefore not usually worthwhile to think about rebuilding an existing engine if it fails or wears out because it will be much more cost effective just to change it. In fact it is a good idea to replace an aging 3.6 with a 4 litre, for which we can provide an inexpensive INTERFACE KIT to adapt the engine management to run with the bigger engine. This comprises an uprated fuel pressure regulator and electronic module which together ensure that the engine runs in the correct area of fuel/ignition mapping even though the air flow will have increased in proportion to the engine size. Still better is that we can supply our Plus Flow kit with the uprated regulator and the airflow meter calibrated to suit the larger engine so no extra wiring is needed. On the earlier 3.6 XJ-S on the 8CU system we would recalibrate the ECU instead.

There is a common fault that afflicts early 3.6 XJ-Ss (1983-87) running on the Lucas 8CU EFI system causing excessive richness and poor running in light and closed throttle conditions. The accompanying note describes the problem and its solution.

Racing options

Most of our road car performance conversions are available in slightly different forms for racing which have more effect higher up the speed range where it is more useful on the track. The Racing High Torque inlet manifold has shorter internal bell-mouths and w also suggest using a Large Bore Throttle. Because intake noise is not a problem on a race car, for the early 3.6 XJ-S (1983-87) we can supply the air filter assembly with a single 3" diameter bell-mouth.

The TT exhaust system is also available to race specification with shorter pipe lengths for the front section to move the effectiveness higher up the speed range. It can also be produced with a single sided rear section with larger diameter pipework exiting on just one side of the car. This provides a worthwhile weight saving over the normal twin outlet system.

Email aj6engineering@ntlworld.com, Tel/Fax:- 0044 (0)1625 573556