| Menu |

| Homepage |

| NEW & REVISED BOOK! |

| Personal intro |

| Philosophy |

| FAQ |

| Exhaust systems |

| Exhaust overview |

| E-type |

| XJ Saloon S1,2,3 |

| XJ40 (AJ6&V12)/X300 |

| XJS |

| XK8/XJ8 |

| TT exhaust explained |

| The Jaguar V12 |

| V12 Performance |

| Stretching the V12 |

| E-type EFI conversion |

| D Jetronic |

| Lucas EFI |

| Vacuum advance |

| Ignition systems |

| V12 throttle linkage |

| Article: V12 Engine |

| V12 Archives |

| The Jaguar AJ6 |

| AJ6 Performance |

| 3.6 Richness |

| AJ6 fault codes |

| AJ6 Archives |

| The Jaguar XK |

| XK Performance |

| Article: XK Engine |

| Article: 4.2 EFI |

| The Jaguar V8 |

| V8 Performance |

| AJ6 Superchargers |

| Superchargers |

| Supercharging article |

| Suspension & Brakes |

| ECU repairs |

| Miscellaneous bits |

| Glossary |

| Prices & ordering |

aj6engineering@ntlworld.com

Updated August 2016

Visitors:

73324180

|

|

A guide to the general principles for increasing the performance of modern engines.

Fundamentally there is a simple rule about getting more performance out of a piston engine. Get it to consume more air (with the right amount of fuel) and it will deliver more performance. More air consumed per cycle will benefit torque, whereas more air in unit time will benefit power. Increasing just air or just fuel rarely achieves much unless the manufacturer got things badly wrong, which is rare. The ratio of fuel to air must remain in the right proportions for proper combustion although some over-richness at full throttle is quite usual as a means of lessening thermal loads on the engine (and catalyst). This may sometimes permit a slight increase in airflow alone to produce a small performance gain.

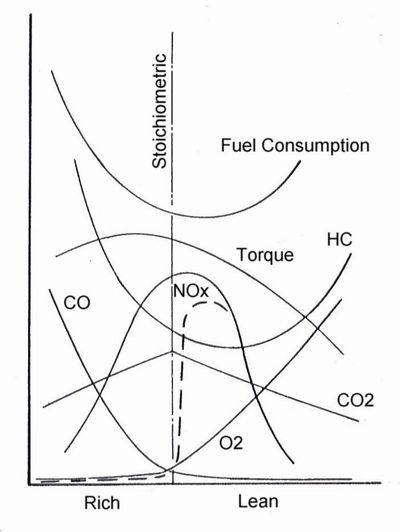

There is a definite relationship between torque, fuel consumption and raw (i.e. before catalyst) gas constituents (see solid lines in diagram) from which one can tell a great deal about what happens inside a spark ignition engine as fueling is shifted either side of the chemically correct (stoichiometric) point.

For instance fueling about 10-15% rich will produce best torque (power) and fueling weak by a similar amount will produce best economy. CO can be used as a measure of rich fueling but O2 content must be used to provide a measure of weak fueling. CO2 reaches a peak of just over 14% at the stoichiometric point, and HC reaches a minimum around the best economy point and then rises as combustion deteriorates with weaker fueling, except in the case of lean burn engines which extend the HC turn up point. NOx is dependent on temperature and pressure so reaches a peak with slightly weak fueling.

Lambda feedback keeps CO and HC close to their minimum levels but NOx might seem to be a problem yet it will be low in cruise conditions anyway and a three way catalyst operating in the critical Lambda stoichiometric "window" will cause it to dissociate (broken line in diagram) into N and O2 which then will oxidise any CO and HC. NOx can also be reduced by lean burn.

Full throttle operation is usually well outside the regime of an emission test so as long as feedback is maintained in off-load conditions there is no reason why performance cannot be improved whilst still complying with emission requirements. However Lambda feedback tends to be intolerant of anything that provokes poor combustion in light throttle operation so things like longer duration camshafts are likely to be problematical.

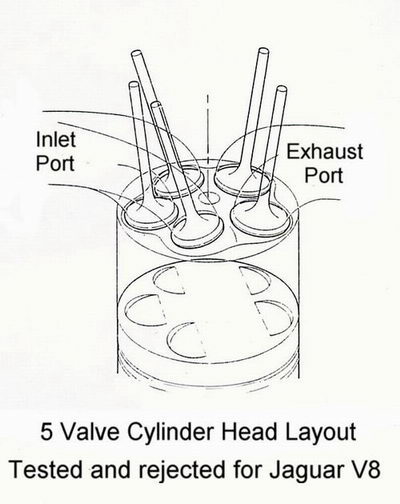

The ports, valves and cams of modern fuel injected engines are designed as a harmonised entity with the induction and exhaust systems so the old ideas of high lift cams, opened up ports and bigger valves are not likely to be very fruitful unless everything else is altered to suit, as they would be for an outright racing engine.

When considering the effect of cams it is important to remember that because of the basic mathematical relationship between area and volume, the ratio of valve area to cylinder volume always favours small cylinders - all things being equal. Of course things like bore/stroke ratio, in-line, hemi or multi-valve configurations make a difference but the hypothesis still holds true when comparing like for like. It is one reason why racing engine designers nearly always aim for the maximum practical number of cylinders, other considerations permitting. It also explains why engines with large cylinders tend to require longer duration cam profiles for the equivalent specific power output. As an example the most famous aircraft piston engine of them all, the Rolls-Royce Merlin, had 12 cylinders each of 2.25 litres displacement, developed maximum power at around 3000 r.p.m. and employed cam duration of around 290 degrees. By contrast the Grand Prix World Championships of 1959 & 1960 were won by a Coventry Climax engine which had four 624 cc cylinders, developed maximum power at 6,750 r.p.m. yet used the same 290 degree of cam duration.

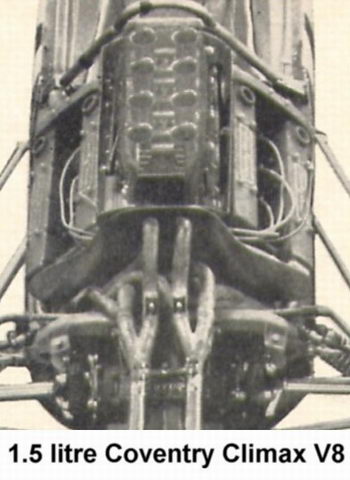

The point is driven further home by the diminutive Coventry Climax V8 which followed (photo). It was the most successful GP engine of the 1.5 litre period from 1961-1965, had individual cylinders of 187.5 ccs and developed its power at around 10,500 r.p.m. Yet again cam duration was 290 degrees. Digressing slightly, the photo shows the very effective exhaust system devised by Climax to get the best from their V8 with its two plane crankshaft. At the time it was derided by some, but much admired and copied by those who recognised its virtues (e.g. Ford's Indy V8 of the 1960s). Coupling the outer cylinders of one bank with the inner cylinders of the other resulted in equal pulse spacing and a significant torque boost. Of course modern racing V8s with a single plane crankshaft achieve the same thing with a separate system to each bank, as applied to later versions of the Climax V8.

Returning to the cam issue, it would be easy to just say "so what" yet there is a clear trend here that any given cam profile will tend to push the power higher up the speed range as cylinder size diminishes - but unless the rest of the engine, the induction and exhaust systems, are designed to keep pace the result will be disappointing. Hence a wild cam that works well in a big V8 is likely to be too much for the smaller cylinders of the Jaguar V12.

Jaguar even produced an engine which gave a back-to-back illustration of the point - the final 2.4 litre version of the XK engine, which used the same straight port head and valves as the 4.2. Although Jaguar used virtually the same cam lift and duration for the vast majority of XK engines and for the entire life of the V12, the 240 had to have cams with reduced lift and duration to produce an acceptable spread of torque but even so peak power still occurred at 5500 r.p.m. More recently Jaguar's 3.2 litre V8 uses milder cams than its 4 litre sibling yet develops peak torque and power at higher speeds. Not surprisingly the specific power is better but the 4 litre delivers better specific torque.

It is our view that because the vast majority of Jaguar V12s hardly ever run above 5000 r.p.m. it might well have been a still better engine had it been given cams with about 20 degrees less duration. This would have benefited economy, emissions and mid-range torque as we found when we produced such a cam back in the early 1980s. Unfortunately it had the obvious effect of slightly reducing peak power so was rather hard to sell even though it knocked about a second off the 0-60 m.p.h. time, so we discontinued it after a couple of years.

Those who think that hotter cams are always a good thing should take note - unless they intend to go on the race track. Although the surge as a hot cam starts to work might feel impressive it can be illusory because the torque is just climbing back to where it should have been all along.

This is all quite fortunate because it means that the starting point for more performance is relatively easy and inexpensive and there is no need to do things like swapping cylinder heads. Upgrading the induction, fuel and exhaust systems undoubtedly gives the most performance gain for the money spent. This is true even for racing although for such purposes we offer similar conversions with more bias towards high engine speeds.

Big engines - with increased bore and/or stroke will always provide a performance gain because torque rises more or less in proportion to engine size. The trouble is that it is a very costly way of doing things - for instance just the 84 mm stroke crankshaft for a 7 litre V12 is a very expensive component and is no use at all without the right pistons, cylinder liners and so on. Standard engines can be cheered up a lot by upgrading the induction, EFI and exhaust systems so it must be obvious that a larger engine needs such upgrading even more if it is to deliver its full potential. Better, surely, to spend money on the upgrades first and then see if more is required.

Electronic fuel injection, ECU repairs, modification and "chip tuning" is an area in which we have been active for many years. Whilst we have probably repaired and reprogrammed more ECUs for V12 Jaguars than anyone else in the business, we have also performed similar work on other Jaguar engines and the Rover V8, which at one time was the mainstay of our ECU business. So-called "chip tuning" started out originally as a means of getting a lot of power out of turbo-charged engines along with increased boost pressures but the principle became rather over-sold because naturally aspirated engines are hardly ever short of fuel at full throttle and cannot really benefit much by such techniques.

On the other hand we are often curious about the value of intake and exhaust modifications which are claimed to produce lots of extra performance without any changes to the fueling. Is it not obvious that if the engine is breathing better and getting more air it will need more fuel to make use of it?

Closely associated with ECUs are the mass airflow meters found on so many modern cars. The only way these can be properly tested is on a flow bench so that the output signal for several different flow rates can be measured accurately. We have such equipment and can bore out and re-calibrate these components for high performance applications.

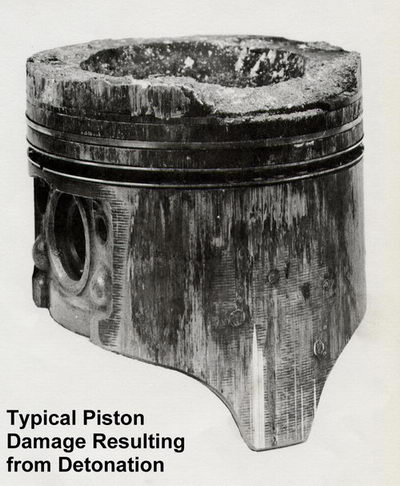

Ignition advance and fuel octanes are inexorably linked with both the performance and reliability of an engine. Some "hot chips" do nothing more than advance the ignition timing - an easy way to get more power. However no motor manufacturer can afford to lose economy or performance by having unduly retarded timing so the safety margin is inevitably cut to the limit and further advance can lead to sudden piston failure with no warning. Of course this also applies to engines with conventional mechanical ignition advance mechanisms like the V12 Jaguar until 1988.

We will dwell on the subject because it is important to understand that gaining extra performance from the engine should never place it at risk.

The destructive enemy provoked by excessive ignition advance is not audible "pinking" but insidious high speed detonation (knock) and its dangerous cousin, pre-ignition.

The diagram shows (slightly exaggerated) how the amount of advance that an engine can tolerate varies from what a conventional centrifugal ignition advance system is capable of providing. The compromises will be obvious and clearly a setup that gives more advance above peak torque (better for power) must mean less below. Programmed advance is better able to match the true requirement but cannot make much difference to the peak torque condition.

The most critical areas are where the lines meet - usually around 1800 - 2000 r.p.m. and again at the peak torque speed where cylinder pressures are highest. The lower speed coincides with the "knee point" of the centrifugal advance curve and knock there is more of an annoyance than a threat because the engine can easily absorb the extra thermal stress. The situation around peak torque and beyond is what puts an engine in danger.

Because of the effects of aging, carbon deposits and so on, the fuel requirement of an engine can easily vary by 6 octane numbers from the newly built condition in cold weather, to the same engine after 30,000 miles, on a hot summer's day following a spell of town driving. Tolerance stack up may add another octane number or two to the equation but the manufacturer has to ensure that every cylinder of every engine will be safe in the worst condition it might encounter.

Knock generally starts to become audible when the ignition timing is advanced by around 3 or 4 degrees beyond the point of being just knock-free so incipient knock can be present without being obvious even to a driver trained to identify it. To put it another way, advancing the ignition timing by 3 degrees requires the octane rating of the fuel to be increased by 2 octane numbers to retain the manufacturer's margin of safety. Of course many engines can tolerate prolonged mild detonation without coming to any harm BUT it is best avoided because in the right circumstances it can suddenly evolve into a self-perpetuating combination with pre-ignition and quickly turn a healthy engine into a wreck without any warning. That is why Jaguar include the following passage in their handbooks and manuals:-

'If, of necessity, the car has to be operated on lower octane fuel, do not use full throttle otherwise detonation may occur with resultant piston trouble'.

(XJ-S Repair Manual, HE supplement, Page 09-3, and elsewhere.)

It is relevant that most Jaguar engines with mapped ignition advance (Marelli V12, hot wire AJ6, etc.) have an air temperature sensor to apply retard at higher air temperatures - evidence surely that the safety margin is pared to the minimum and more advance would be risky.

We therefore never advise advancing the ignition timing in the pursuit of performance, other than when circumstances will allow it to be done with safety.

Induction systems are probably the most rewarding area to modify on most engines because although the inlet manifolds are generally very well designed these days the need for noise suppression often compromises the true potential. The first step is usually to open up the entry of the system so that it is not so restrictive. The small intakes of the Jaguar V12 are a typical example but whilst it is simple to chop off the intake tubes from the air filter boxes and attach 3" diameter trumpets, the induction noise is then more than most people would find acceptable. Nevertheless there are ways to increase the flow capability of the system without increasing the noise level by very much. However it must be remembered that for any induction system to be truly effective it will have to be designed or modified with full regard for the unsteady flow dynamics that dominate the whole process rather more than simple matters of restriction. Tuned ram effects can completely overwhelm considerations based on simple flow.

The airflow meters found on many engines are undoubtedly a source of restriction. We deal with this by boring the hot wire type out to a larger size or, in the case of the flap type we reduce the spring load acting on the flap. In both cases we calibrate the circuitry or ECU accordingly.

Cold air intakes are well known as a means of improving performance. A drop in air temperature of 30 C equates to about 10% greater air density and a roughly equivalent torque gain. However this has an adverse effect on fuel efficiency at part throttle because of increased pumping work. The denser the air the more the throttle must be closed to restrict power, which increases negative pumping losses. The rule therefore is "cold air for power, hot air for economy".

All injected 5.3 V12's draw air from behind the radiator, but before condemning the arrangement for sacrificing power by inhaling heated air it should be realised that there is some subtlety at work here. At idle the under-bonnet air is certainly hot but as the car speeds up so air passes through the radiator more rapidly and heats up less as it does so. Whilst the intake air temperature at idle might be obviously hot, around 60-70 C, at motorway speeds it will be not much above 40 C so a reasonable compromise between low speed economy and high speed power is achieved with no need for complication at all.

Actually there is more to a cold air intake than just trying to scoop air from ahead of the radiator because all sorts of flow reversals take place through a radiator and around the front of a car, so without confirming by measurement it is impossible to say that any intake is really capturing cold air. The 6 litre XJ-S was introduced with "cold air intakes" yet the specific power (51 b.h.p. / litre) was less than the previous year's 5.3 XJ-S engine (53 b.h.p. / litre) with the original much derided intake arrangement, a figure equaled by the same 6 litre engine in the XJ40 saloon with intakes drawing from the wheel arches. The difference of compression ratio is not significant because the lower ratio of the 6 litre permits more ignition advance so has no real effect on specific power.

It is quite difficult to say exactly what power is achieved with any intake at speed on the road. Subjective assessment counts for very little. The only real answer is to take exactly comparable air temperature sensor readings from the different installations and then calculate back to the normal corrected power figures.

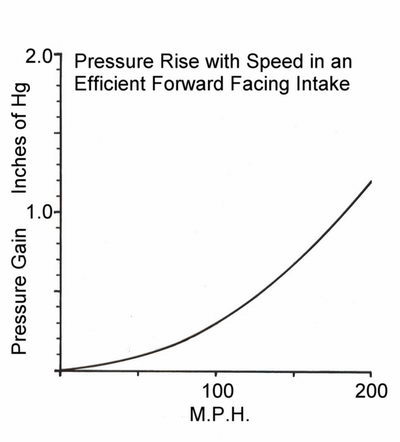

Then there is the matter of intake size and the effect of forward motion. Some people think that that the biggest possible forward facing intake will cram more air into the engine under the effect of forward motion. Sadly it is not that simple and if the intake captures more air than the engine can consume it simply spills the excess over the side and creates drag. Calculation shows that at 100 m.p.h. the ideal forward facing intake for one cylinder bank of a 300 b.h.p. Jaguar V12 at maximum power would need an area of approximately 4.6 square inches, or 2.5 inches diameter. Slowing the air down in the air filter box will convert velocity into pressure - but only by about 0.3 inches of mercury (0.15 p.s.i.). This is because the pressure build up from a well designed intake follows the square of the speed and is not very significant below about 150 m.p.h. (see graph). Indeed at 150 m.p.h. the same V12 intake only needs to be about 2" diameter and will create a pressure rise of about 0.7 inches of mercury (0.35 p.s.i.). It is instructive to consider the relatively modest intake size (around 20-25 sq. ins) of a typical 900 b.h.p., 200 m.p.h., F1 car.

Larger throttles with a more efficient entry profile are a useful way of getting more air into the engine which works particularly well on the Jaguar V12 in combination with improvements to the filter and intake system.

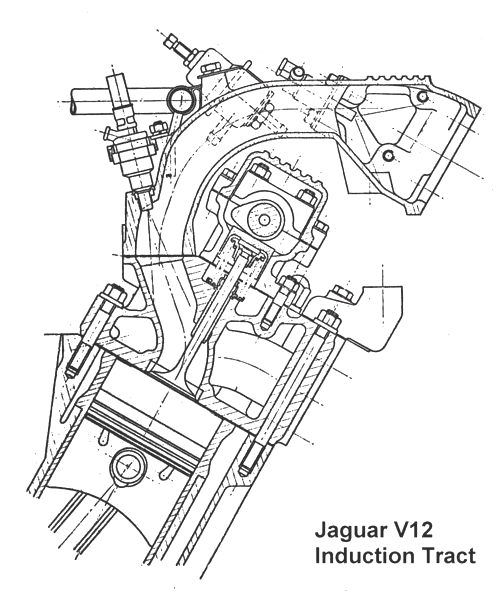

As there are 120 degrees between firing strokes on each bank it follows that at any moment only two cylinders will be inhaling air from either plenum chamber (diagram). As the individual tracts are nominally 1.34" (34 mm) diameter the effective tract area flowing at any one time is barely 2.8 sq. inches whereas even the standard throttle area (2.5" diameter) is 4.9 sq. inches - or nearly double the active tract area.

We know that boring out a pair of the standard throttles to 2.875", as we have been doing for about 20 years, provides enough flow capacity for around 600 b.h.p., if everything else is properly developed for the purpose, so one might reasonably wonder why they might help a standard engine of around half that power.

Actually it isn't so much about flow - it is more about the interconnection of two chambers, the manifold plenum and the air filter box. The only thing separating them is the throttle and the larger the throttle the more these two volumes can act as one. When the V12 manifolds were designed over 30 years ago not much was known about the relevance of plenum volume although it was generally considered that if it should not be too large or responsiveness would suffer, which is still true. It is now known that in a tuned, single intake, plenum induction system, top end power increases with the volume of the plenum. Ten times engine capacity would not be too big - indeed bigger still would be better, though rather impractical. Obviously the V12 plenum volume, at around 1.7 litres, is much too small but increasing throttle area helps to couple it to the filter volume for a total approaching 4 litres. Also because the filter volume is always at atmospheric pressure there is not much delay in filling the manifold when the throttle is opened quickly which must help responsiveness (assuming the appropriate acceleration fueling is provided).

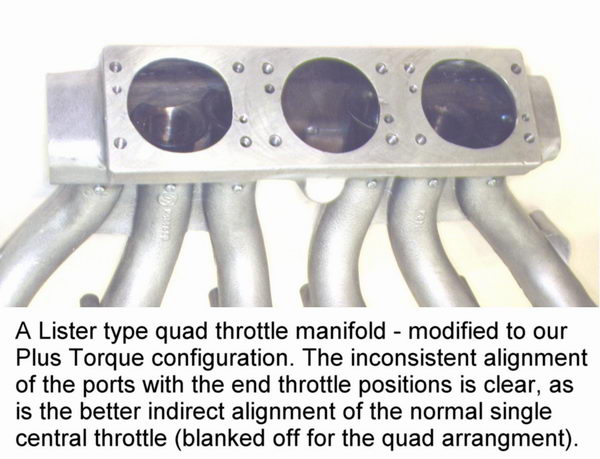

This all might seem to be a good argument in favour of duplicating the throttles (i.e. a quad throttle system) but while the increased area may well be a good thing, the idea breaks the rule that incoming passages should not be aligned with outgoing ones. Quite apart from the obvious flow bias there will be a significant difference in the way pulses diffuse from the ports depending on their alignment with the throttles so it would be exceedingly difficult to achieve equal conditions in all of the individual tracts.

The 6 litre saloon has a quite different induction system on more conventional lines which, not surprisingly, does not benefit from enlarged throttles.

Moving on from the plenum chamber the geometry of the individual inlet tracts from the plenum chambers is very important because they can have a powerful role to play in charging the cylinders.

Simple flow improvements will have most effect at high engine speeds. Applying more scientific principles to the induction system can reap large benefits by harnessing resonant waves in the system, in a similar way to extractor type exhaust systems, to push extra air into the engine at almost any chosen speed, determined largely be the length and diameter of the passages. This is now a widely used technique but the first deliberate Jaguar application was on the fuel injected D Type in the late 1950s (see 4.2 section).

The ultimate systems for racing use separate throttles, as we have produced for both V12 and AJ6 engines, but it is now normal to feed all the tracts from a voluminous air box which is an important part of the whole system. For more practical applications the widely used single throttle and plenum chamber arrangement is usually better because it provides a wider torque band and makes fuel and ignition much easier to control. Slide throttles were popular at one time but even F1 racing engines have reverted to conventional butterfly throttles these days.

The high torque inlet manifolds that we produce for our Plus Torque conversions make use of the same technology which is far more powerful than the porting, gas flowing and polishing that so many old go-faster books espouse. All modern production inlet manifolds heavily exploit these principles helped by the accuracy of modern manufacturing methods using plastics and composites. However none of this is any use unless the fuel input is altered to keep pace with the extra airflow and the rate at which it changes. Not only that but use of large throttles, or adding extra throttles, magnifies the rate at which airflow can increase as the throttle is opened. It is therefore very important that the ECU is modified to react accordingly otherwise the engine response will become more sluggish unless the pedal is stamped to the floor.

Racing versions of many of our performance kits are available with the emphasis shifted higher up the speed range. The photo shows the short trumpet race version of the XK Plus Torque manifold shown above. Similar variants of V12 and AJ6 Plus Torque kits are available to order.

Supercharging with a positively driven compressor has become increasingly popular for many applications in recent years because of the wide torque band and immediate response which turbocharging can never quite match. Jaguar's XJR models are good examples offering tremendous performance to make the standard V12 look positively sluggish. Our associate AJ6 Superchargers, detailed in a later section, has unrivalled experience of supercharging all sorts of engines from motorcycles to top fuel dragsters.

We sometimes get requests for pulleys to speed up the supercharger on an XJR in the expectation of finding more power but sadly it isn't that easy. Speeding up the blower usually boosts torque quite usefully but the power gain can be disappointing because at high speeds the overdriven blower heats up the air too much. A treatise on the subject of supercharging can be found elsewhere on our website which delves into the subject in some depth for those who are interested.

We also sometimes receive requests about supercharging this or that Jaguar engine, the idea being that one can just take a supercharger, bolt it on, run a belt drive to it, pipe it into the engine and drive away. In reality a lot of serious engineering is involved. We can certainly do it but the price would be rather more than most people would really wish to spend so commercial viability would be somewhat elusive.

Exhaust Systems are a popular area to think about upgrading for performance and longevity. Silencer Substitute Pipes are an inexpensive starting point for most Jaguars, including some carburettor engined cars, the idea being to replace the most restrictive pair of silencers in the system with matching straight through stainless steel pipes. This is undoubtedly the most cost effective performance modification anyone can buy. The car is noisier, but not by much and is about right for those people who consider that, for a car with performance pretensions, a Jaguar is actually too quiet.

Stainless Steel Systems with all straight through silencers are an option we offer as a high quality replacement for a tired factory system, giving approximately the same performance as Silencer Substitute Pipes.

Large Bore Systems in stainless steel are also offered by us but we only recommend them as a performance option if the entire original system is at the end of its life. All silencers are of straight through type so there is no need to use Silencer Substitute Pipes. The performance gain is a little more than the Silencer Substitute Pipes provide when added to a standard system, and mainly at the top of the speed range. There is a common fallacy that power somehow increases with the size of the exhaust pipes. If a pair of 2¼ " diameter pipes are good enough for a 484 b.h.p. Ferrari 550 Maranello then not too much should be expected from fitting a large system to a 300 b.h.p. Jaguar V12. This option is for those who require a quality system with a moderate performance gain and a slightly deeper exhaust note.

Whilst a big-bore exhaust system can produce a moderate performance gain it represents the passive approach of simply reducing restrictions to flow and therefore has rather limited potential.

A much better way is to use an active system that will induce flow to take place beyond that which would otherwise be possible. All racing systems work in this way and are known as Extractor Systems. Our TT Performance Exhaust Systems are of this type and fueling changes are needed to get the most from them although the 6 cylinder Jaguar engines with mass airflow meters deal with this automatically.

The operating principle is all about exploiting the initial discharge of exhaust gas from each cylinder to create a pressure wave that travels at the speed of sound along the system and reflects back from the open pipe end. The returning wave becomes negative (low pressure) and therefore can help to scavenge the cylinder and draw fresh charge in through the inlet valve. Obviously the length of the pipe is critical to synchronise this action so that it occurs at the right time and the effect can only work over a particular range of engine speeds.

Apart from the wave effect the mass and velocity of the discharging gas is also important. The inertia of this fast moving plug of gas pushes out residual exhaust ahead of it and creates a depression in its wake. The diameter of the pipe is critical because of its influence on gas velocity and generally a small pipe diameter will work better to provide a desirable wide torque band.

If the exhaust ports of a number of cylinders are grouped together so that the exhaust discharges occur at even intervals the above effects can be synergistic so that each cylinder helps its neighbour. For a 6 cylinder engine this works conveniently with the front three cylinders as one group and the rear three as another. A typical multi-branch header would have separate pipes from each cylinder but in practice, with normal valve timing there is hardly any overlap of the exhaust valve events of the three cylinders, so it is not of much consequence if the standard exhaust manifold is retained. What matters is that the merge point to the other group of three is not close by as usual but at a greater critical distance away. The same obviously applies to each bank of a V12. Our TT systems for 6 and 12 cylinder Jaguars keep the groups of three cylinders separate for a distance of over a metre from the engine instead of merging just below the manifolds as from the factory.

A question that sometimes arises is the idea of having a balance pipe, or cross-over, between the two sides of the engine - the thinking being that if it works on a V8 it must do something for a V12.

It is true that a cross-over can benefit conventional V8 engines (with two plane crankshaft) but only because they have an uneven firing sequence along each cylinder bank, which creates the rather delightful V8 exhaust note. A consequence of having two cylinders firing consecutively on each bank is that the flow rate is briefly doubled, then later in the cycle the long gap between firing impulses causes it to be halved, compared to the average flow rate. The temporary high flow rate means the V8 can benefit from using larger pipe sizes than other engines and a cross-over pipe can help to even out the impulses. It is not obvious to the eye but the Jaguar V8 incorporates a cross-over within the main silencer box.

A V12, on the other hand, has equally spaced firing impulses along each bank creating an even sequence of pulses. There is no flow variation to require a balance pipe and the system does not have to contend with brief periods of peak flow so pipe sizes can be smaller. The only reason the V12 E Type had a balance pipe was simply to tune the exhaust note.

It is perhaps relevant to mention that a cursory glance at any F1 exhaust system will demonstrate conclusively that exhaust gases do not at all mind going round tight bends. The 6 into 1 system (photo) from an F1 Ferrari illustrates the point. Also noteworthy is the modest diameter of the tailpipe - about 2.75" for an engine producing around 800 b.h.p.

Surely therefore a Jaguar engine of less than half that sort of power can be quite adequately served by a well designed extractor system of modest size. There is obviously no reason for concern about any possible restriction caused by the bends around the drive-shafts on a Jaguar. There is room if necessary to get 2" pipes through the axle area which is plenty big enough for all but the most extreme road going Jaguar.

All of our exhaust system parts are manufactured from high grade non-magnetic 304 or 316 grade stainless steel with nominally 1.5 mm /16g wall tubing and have a lifetime guarantee against corrosion. We ask that this point be remembered when comparing with other products which often will be made from lower grade 409 magnetic stainless steel, more akin to an extended life mild steel which can discolour and deteriorate, particularly in the hot conditions following a catalyst.

We do not offer exhaust systems with catalysts at the present time although most systems are available with fittings for Lambda feedback sensors if required.

MAKING SURE THE EXTRA PERFORMANCE CAN BE SAFELY USED

It would be irresponsible and dangerous to increase the performance of the engine beyond the capabilities of the car. Fortunately, Jaguars have considerable reserves in this respect - as long as everything is in sound condition.

Brakes must be the first consideration and sadly they do tend to be neglected. How many people actually follow the manufacturer's advice to renew brake fluid every two or three years? Because brake fluid absorbs water even through the brake hoses it steadily deteriorates and a driver braking hard repeatedly or from high speed can find out about it the hard way. The answer is not to panic and fit bigger brakes as some suppose. All that is needed is to have the system in the same condition it came from the factory. With good discs, fluid and pads, few drivers will have any problem at all - and a slightly harder pad material should suffice for those that do reach the limit.

Suspension is an area of a Jaguar which needs some thought. The original design is very good for a luxury high performance car. The enthusiastic driver may well appreciate firmer damping and roll stiffness but it is easy to go too far and spoil the ride qualities. It takes a skillful suspension engineer to achieve the delicate blend of firm handling with acceptable ride that is required for a Jaguar. We rely on the advice of HBE, a company who are notably successful in this respect

Steering accuracy is essential for any high performance car but this deteriorates as the various rubber mountings and bushes which contribute so much to Jaguar refinement degenerate with age and contamination. If they require renewal it is sensible to replace them with polyflex items which provide more positive location without too much loss of the compliance so necessary to maintain the unique qualities of a Jaguar.

Cooling system deficiencies must be remedied before indulging in any performance increases or the shortcomings may suddenly become very obvious. Despite what some might claim there is nothing at all wrong with Jaguar cooling systems as long as they are in good condition. That they are sometimes complicated (particularly the V12) does not mean they can be neglected in any way. Because of the major aluminium engine parts it is essential that the coolant always has the required level of corrosion inhibitor or radiator blockage is certain to happen and then the engine will overheat and possibly suffer damage. If the engine starts to overheat for any reason it is folly to continue to drive it - an overheating 4.2 XK engine can be destroyed in half a mile and a badly overheating V12 may suffer with valve seats coming loose after switching off.

Exhaust Emissions can govern what modifications can be done to a car and must be taken seriously. All of our road going induction or ECU modifications can be supplied to be compatible with the emission system required for any particular market and will not adversely effect the ability of the car to pass the usual tests. In practice the yearly MOT checks in the UK and 2 yearly smog checks in the USA are not very stringent and can be passed quite easily without a catalyst being present although Lambda feedback must usually be retained. Except for those cases where a visual check has to be made to verify the presence of a catalyst, it can therefore be acceptable to use a non-catalyst system without falling foul of the law. This applies to the UK and some US states. The situation in Germany is slightly different where cars without catalysts are subject to a tax penalty and restriction of use.

High lift or long duration camshafts are always likely to cause problems with emissions testing.

In the event of any uncertainty over this point we will gladly discuss and advise on individual requirements.

A FINAL NOTE

If a vehicle is known to have some sort of fault in the engine, ignition system or fuel injection system the problem should be diagnosed and repaired before considering fitment of performance parts. It is false hope to believe, for example, that fitting an upgraded ECU will resolve an existing problem. Of course if the ECU is faulty then the upgraded item will resolve it and improve the car but it is essential to identify that it is the cause first. Much as we want to sell our conversions to everybody we have no wish to do so if there is reason for doubting that satisfactory operation will not be obtained. We do not mind giving advice to help those having difficulty diagnosing problems.

Email aj6engineering@ntlworld.com, Tel/Fax:- 0044 (0)1625 573556