| Menu |

| Homepage |

| NEW & REVISED BOOK! |

| Personal intro |

| Philosophy |

| Intro technics |

| FAQ |

| Exhaust systems |

| Exhaust overview |

| E-type |

| XJ Saloon S1,2,3 |

| XJ40 (AJ6&V12)/X300 |

| XJS |

| XK8/XJ8 |

| TT exhaust explained |

| The Jaguar V12 |

| V12 Performance |

| Stretching the V12 |

| E-type EFI conversion |

| D Jetronic |

| Lucas EFI |

| Vacuum advance |

| Ignition systems |

| V12 throttle linkage |

| Article: V12 Engine |

| V12 Archives |

| The Jaguar AJ6 |

| AJ6 Performance |

| 3.6 Richness |

| AJ6 fault codes |

| The Jaguar XK |

| XK Performance |

| Article: XK Engine |

| Article: 4.2 EFI |

| The Jaguar V8 |

| V8 Performance |

| AJ6 Superchargers |

| Superchargers |

| Supercharging article |

| Suspension & Brakes |

| ECU repairs |

| Miscellaneous bits |

| Glossary |

| Prices & ordering |

aj6engineering@ntlworld.com

Updated August 2016

Visitors:

73614940

|

|

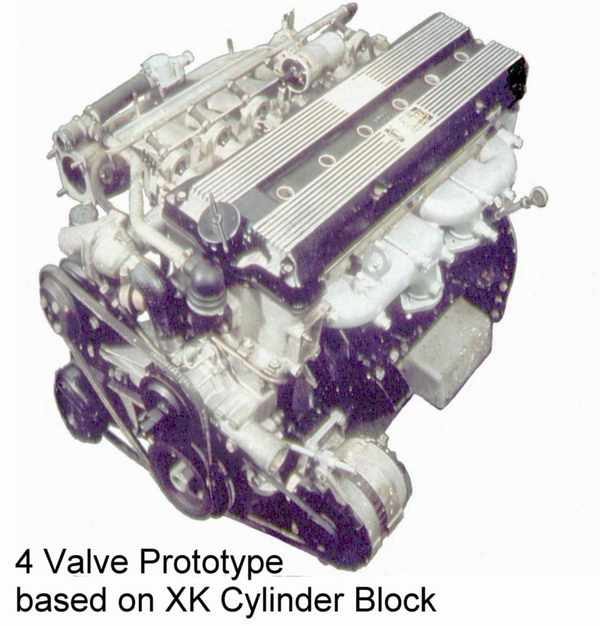

1. An early prototype stage in the AJ6 engine gestation process. This is actually based on a variant of the XK cast iron cylinder block but the head layout already had features like the head bolts passing through the camshaft bearing caps that carried over to the AJ6 design. It can be seen that the exhaust and induction manifolding was still handed in the way of the XK.

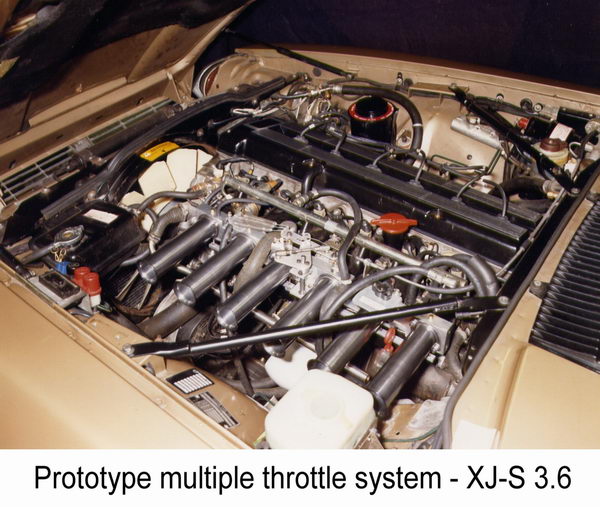

3. Here is the same throttle system installed on a 3.6 XJ-S. This produced a power gain of about 50 b.h.p. from an otherwise standard engine when used with a less restrictive exhaust system. Intake pipe length was critical - shortening the trumpets by 1.5" reduced the power gain by nearly 20 b.h.p. Adjustable length trumpets were used to find the ideal dimensions to use.

4. The production version of the multiple throttle system with the main assembly machined from a casting, chrome plated bright-work and a custom made K & N filter.

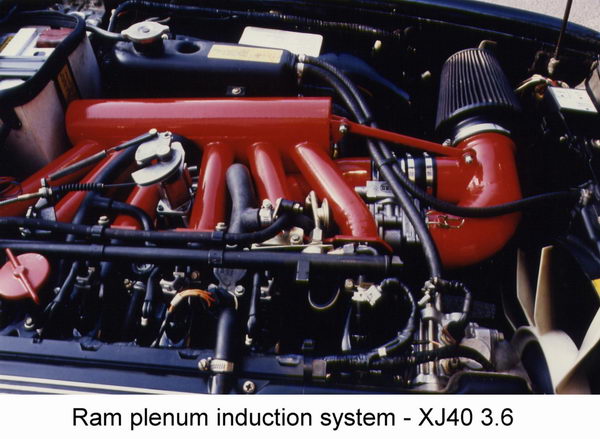

5. A prototype of our Ram Plenum induction system for the AJ6 engine. This was a highly resonant tuned pipe system designed to work with the Lucas 9CU and 15CU engine management systems. The restriction of the hot wire airflow meter was resolved by adding a bypass orifice to double the breathing area, and some electronic changes to compensate for the different load signal. The throttle was 3.5" diameter mounted on ball races to overcome the effects of vacuum induced friction on the spindle. When on song it was incredibly noisy, to the point of being painful, and only became civilised by adding a resonator inside the intake duct. It produced a very strong power band from 3000 to 6000 r.p.m.

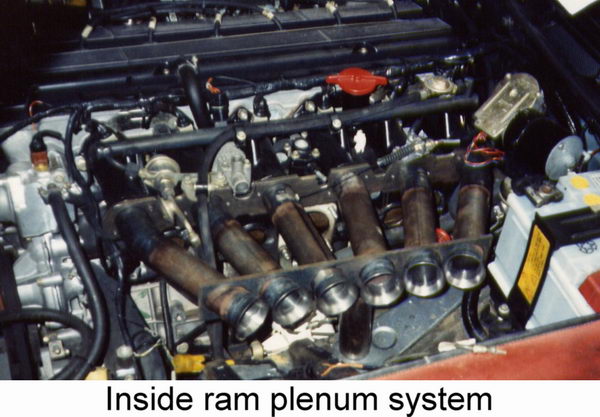

6. This shows the individual tuned length pipes of the Ram Plenum system - before the plenum chamber was welded in place. The wave action within the pipes was augmented by powerful resonances in the main intake duct.

Email aj6engineering@ntlworld.com, Tel/Fax:- 0044 (0)1625 573556