| Menu |

| Homepage |

| NEW & REVISED BOOK! |

| Personal intro |

| Philosophy |

| Intro technics |

| FAQ |

| Exhaust systems |

| Exhaust overview |

| E-type |

| XJ Saloon S1,2,3 |

| XJ40 (AJ6&V12)/X300 |

| XJS |

| XK8/XJ8 |

| TT exhaust explained |

| The Jaguar V12 |

| V12 Performance |

| Stretching the V12 |

| E-type EFI conversion |

| D Jetronic |

| Lucas EFI |

| Vacuum advance |

| Ignition systems |

| V12 throttle linkage |

| Article: V12 Engine |

| The Jaguar AJ6 |

| AJ6 Performance |

| 3.6 Richness |

| AJ6 fault codes |

| AJ6 Archives |

| The Jaguar XK |

| XK Performance |

| Article: XK Engine |

| Article: 4.2 EFI |

| The Jaguar V8 |

| V8 Performance |

| AJ6 Superchargers |

| Superchargers |

| Supercharging article |

| Suspension & Brakes |

| ECU repairs |

| Miscellaneous bits |

| Glossary |

| Prices & ordering |

aj6engineering@ntlworld.com

Updated August 2016

Visitors:

73533064

|

|

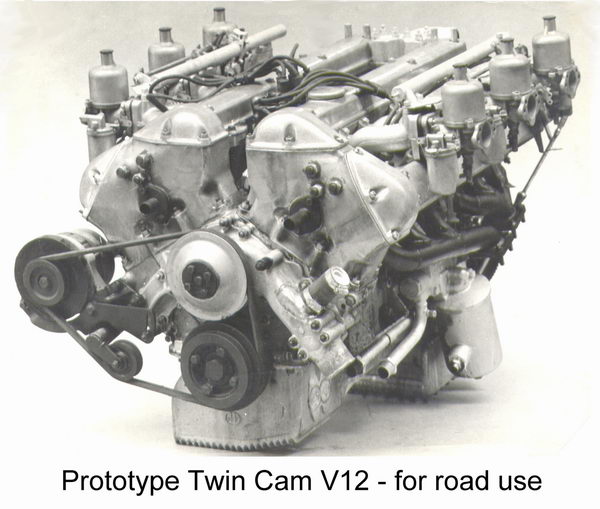

1. An early road going V12 prototype displaying a strong family resemblance to the XK. Notable are the triple SU carbs on each bank leading onto downdraft inlet ports between the camshafts and also the pair of 6 cylinder distributors. The included angle between the valves was closed to 60 degrees compared to the 70 degrees used on the production XK which provided a shallower combustion chamber better suited to the over-square bore/stroke ratio.

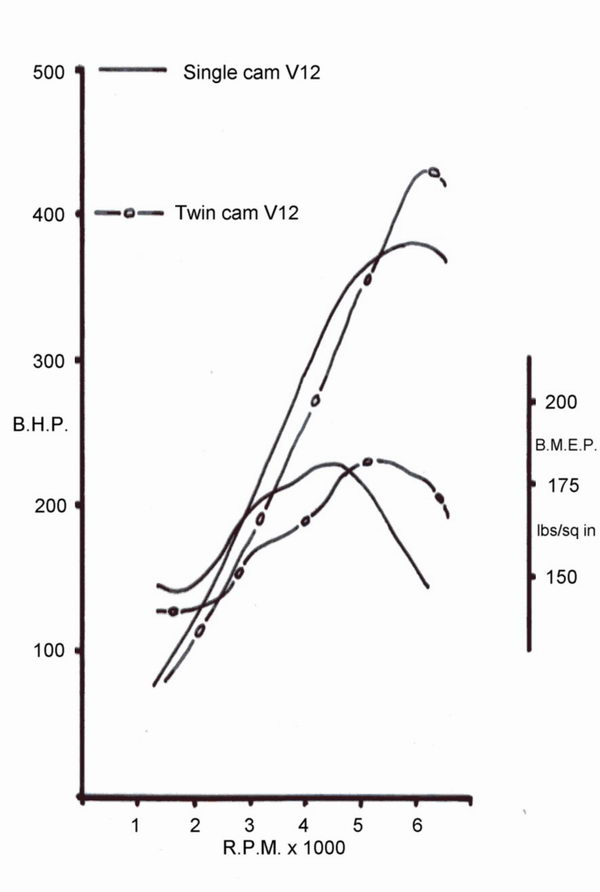

2. Power curves for the twin cam V12 compared with the single cam version. Quite apart from the practical considerations of weight, bulk and cost, the reason for preferring the single cam layout is obvious.

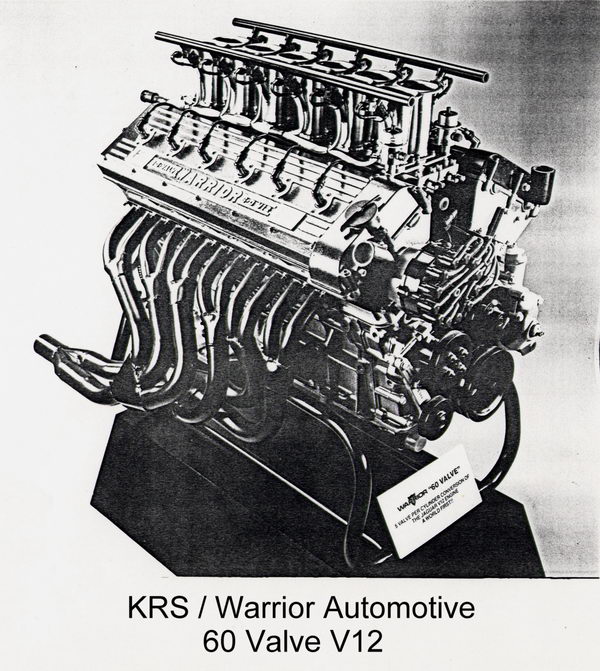

3. Jaguar also experimented with the 4 valve layout in the early 1970s . Performance was impressive but pragmatism still favoured the single cam engine. Note the separate camshaft carrier which easily differentiates these engines from the later TWR 4 valve engines. It was one of these engines that TWR built up with revised induction and exhaust, and new cam covers, for installation in the prototype XJ220.

4. 60 valve (5 per cylinder) heads on Jaguar V12 by KRS / Warrior Automotive exhibited at the 1988 Racing Car Show. Never completed to running condition, KRS went bust at the end of 1989.

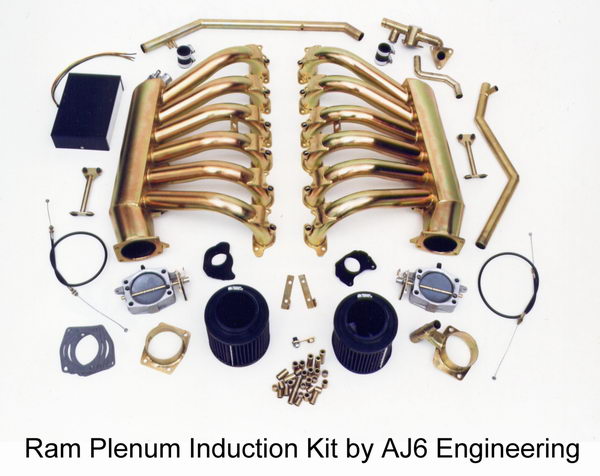

5. Our Ram Plenum tuned length induction system kit for the V12 produced during 1986-92. This beefed up a standard engine by nearly 70 b.h.p. but was too expensive to manufacture. Close to 600 b.h.p. was possible from a race engine. We first started producing our large throttles for this application.

6. The Ram Plenum induction installed in an XJ-S. All ancillaries could be retained even including the valve block for Teves ABS brakes.

7. A Multiple Throttle system we created for power boat racing. Notable are the long tract lengths in pursuit of maximum torque.

8. Power and torque curves for the early D Jetronic injected 9:1 compression V12 of 1975-80.

9. Power and torque curves for the 10:1 compression V12 made for one year 1980-81. This engine introduced the Lucas P Digital EFI system with the first 6CU control units but retained OPUS ignition.

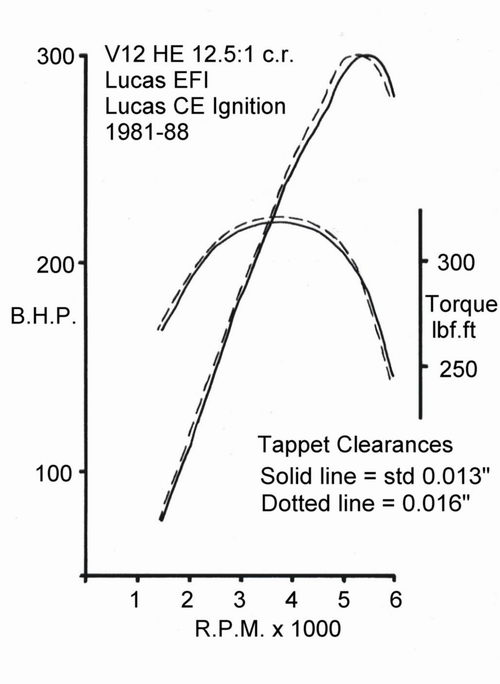

10. Power and torque curves for the 12.5:1 compression HE V12 from 1981-88. The 6CU control unit was significantly updated and introduced Lucas Constant Energy ignition with the unusual twin coil arrangement to deal with the heavy spark demands. Also showing how wider tappet clearances could influence performance.

Email aj6engineering@ntlworld.com, Tel/Fax:- 0044 (0)1625 573556