| Menu |

| Homepage |

| NEW & REVISED BOOK! |

| Personal intro |

| Philosophy |

| Intro technics |

| FAQ |

| Exhaust systems |

| Exhaust overview |

| XJ Saloon S1,2,3 |

| XJ40 (AJ6&V12)/X300 |

| XJS |

| XK8/XJ8 |

| TT exhaust explained |

| The Jaguar V12 |

| V12 Performance |

| Stretching the V12 |

| E-type EFI conversion |

| D Jetronic |

| Lucas EFI |

| Vacuum advance |

| Ignition systems |

| V12 throttle linkage |

| Article: V12 Engine |

| V12 Archives |

| The Jaguar AJ6 |

| AJ6 Performance |

| 3.6 Richness |

| AJ6 fault codes |

| AJ6 Archives |

| The Jaguar XK |

| XK Performance |

| Article: XK Engine |

| Article: 4.2 EFI |

| The Jaguar V8 |

| V8 Performance |

| AJ6 Superchargers |

| Superchargers |

| Suspension & Brakes |

| ECU repairs |

| Miscellaneous bits |

| Glossary |

| Prices & ordering |

aj6engineering@ntlworld.com

Updated August 2016

Visitors:

73745924

|

|

It is a constant source of amazement to the writers that companies such as Jaguar and Mercedes, the latter especially in view of its reputation for precision and efficiency, should market supercharged engines for which the supercharger selected, a Roots device, is probably the least efficient of the types available. It is undoubtedly well engineered and produced in large numbers at an attractive price by the Eaton Corporation but it cannot escape the limitations of its working principles.

The engineers at Jaguar and elsewhere must know about the relative efficiencies of the different types of supercharging devices and how much engine performance can be affected, or are they shackled by the accountants into accepting ready availability and low price as the overriding factors? The supercharged Jaguar V8 is obviously an outstanding power unit - but it could be so much better! Its performance can be easily beaten by supercharging the humble pushrod Rover V8 - as long as it is done with high efficiency.

We all probably understand supercharging at a basic level - take air at atmospheric pressure and pump it into an engine in greater quantities than would normally be the case and quite obviously the power output of the engine will be increased, assuming that fuel is added in proportion.

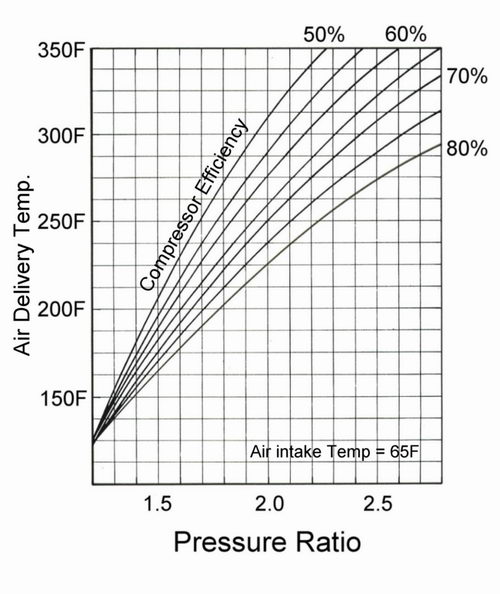

The point which few people seem to realise, and text books devoting space to the subject seem to miss, is that the efficiency of the supercharger is a vital factor in how a supercharged engine system will perform. Efficiency of the supercharger, and here we are talking about adiabatic, or compressive efficiency, determines 2 key factors - firstly, the power the process will consume and secondly, the temperature of the air it will deliver to the engine. In essence, adiabatic losses within the supercharger appear as raised delivery air temperature, thus causing a higher boost pressure, without increasing charge density, and also predisposing the engine to the evils of detonation.

Every enthusiast who ever tinkered with an engine knows that cool air is better for power simply because of its greater density. The same is true of supercharging. The trouble is that any act of compression must heat up the air involved so the trick is to keep this heating effect to the absolute minimum. The best way to achieve this is to compress the air to the pressure required as efficiently as possible. The delivered air will still be quite hot so unless the level of boost is going to be less than about 6 lbs (0.4 bar) charge-cooling (inter-cooling) will usually be necessary to bring the temperature down further for best effect, but an efficient compressor is the ideal starting point.

If any proof is needed of how important supercharger efficiency is we only need to look back to the dark days of World War 2 and consider the tremendous development effort applied to the legendary Rolls-Royce Merlin aircraft engine, a 27 litre V12. Starting out with 790 b.h.p. in 1933, redesigned cylinder heads and many detail improvements lifted it to 1030 b.h.p. by 1939, yet by 1945 the in-service output had more than doubled to 2385 b.h.p. with experimental engines giving 2620 b.h.p. at 36lbs of boost!!! Whilst the availability of high octane fuel was an essential factor the major power gains were almost entirely due to improvements in the supercharger and induction system.

Aircraft superchargers were virtually all of the centrifugal type and Rolls-Royce installations started out with an efficiency of around 37% rising to nearly 80% by the end of the war. The final 10-15% which made the real difference came about largely through the efforts of Stanley Hooker (later Sir Stanley) who became a key figure in the British jet engine business (he was even called out of retirement to knock the RB211 into shape after it had bankrupted Rolls-Royce in 1971).

Aircraft piston engine superchargers were the ancestors of jet engine compressors, which have since evolved to the point where the (axial) compressors of modern jet or turbofan engines approach 90% efficiency and achieve pressure (i.e. compression) ratios near to 50:1. Unfortunately the axial compressor, which can be thought of as a sequence of fans interspersed by rings of fixed blades to direct the flow, is at its best working with far greater amounts of air than even the most powerful piston engine would require and does not seem to work so well when scaled down. It is known that an axial compressor was designed by Rolls-Royce in the early 1980s for an unspecified motor racing application but it never reached fruition. In the long term such a device might become viable, possibly with ceramic technology, but it will have to fight hard against other developments of more obvious potential.

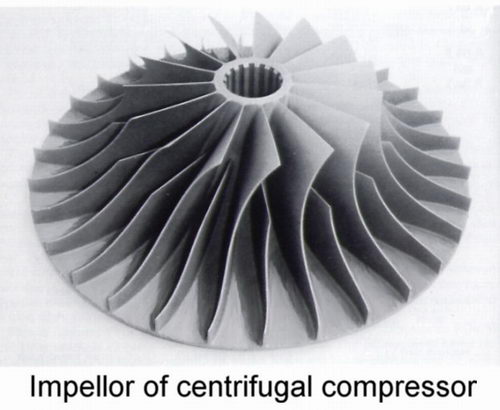

Centrifugal superchargers are aerodynamic devices using a rotating impeller to accelerate the incoming air to high velocity which is then converted into pressure as the air slows down in the surrounding diffuser. The delivery is proportional to the square of the speed of rotation of the impeller, which is fine for an aircraft engine designed to run at a set speed, with the throttle controlled barometrically, but not so useful for a motor vehicle power unit with the usual wide range of operating speeds. To illustrate the point the boost at 6000 r.p.m. would be 4 times that at 3000.

The impeller must rotate at very high speed to do anything useful and therefore has a great deal of inertia which can subject a gear or belt drive to very high loads with changes of engine speed. Indeed aircraft engine supercharger drives always incorporated some sort of cushioning device to absorb these loads. A turbocharger gets round these problems by driving the impeller via an exhaust turbine to achieve the necessary high speed of rotation, simply dumping excess exhaust through a 'waste-gate' when the required amount of supercharge is achieved, thus being able to function over an acceptably wide range of engine speeds. Inertia of the impeller and turbine give rise to what is known as turbo-lag which can never be entirely eradicated even though there are ways of making it far less noticeable.

Obviously, a centrifugal supercharger driven from the engine will normally only provide useful boost at high engine speeds, so if top end power is the only requirement it might suffice, but the history of centrifugal blowers in racing has not been very impressive. The V16 BRM of the early 1950s, like the Novi V8 Indy engine dating from the same period, promised much but found success to be elusive.

To be make any contribution to mid-range torque, some sort of variable drive is needed, or the wasteful alternative of dumping excess charge at high speed. There is a type of epicyclic friction drive that seems quite popular at present which works rather like a viscous coupling - slippage occurs at a certain torque loading so the impellor speed can only continue to rise as long as the engine is able to consume more air.

Not surprisingly such an arrangement works quite well with fairly wild camshafts to keep the engine breathing at higher speeds, but this must be at the expense of having poor torque low down. It seems there is also a problem achieving consistent slippage behaviour from car to car so this essentially simple solution is not without its drawbacks. One might reasonably conclude that the centrifugal supercharger, despite its appealing compactness and simplicity, is therefore still not very promising as a supercharger for a motor car.

The popular Roots blower consists of a pair of intermeshing lobed rotors which carry volumes of air between the lobes from the intake port to the delivery port in similar fashion to a gear oil pump. It has a very significant drawback in its method of operation - there is no change of volume and therefore no compression in its action. The pressure of the charge can therefore only increase at the point of discharge as it becomes exposed to the higher pressure beyond, so flow reversals and considerable turbulence occur, rather than a steady delivery at the required pressure.

Let us consider how the action of a displacement device like the Roots blower differs from that of a true compressor. Imagine a simple hypothetical reciprocating piston compressor in 2 versions, both delivering air through a valve into a chamber in which the pressure is significantly above atmospheric. Both inhale a fresh charge of air on the piston down-stroke but in one version the delivery valve opens at the commencement of the up-stroke whilst in the other the delivery valve opens only when the charge of air has been compressed to the same pressure as the chamber. Both convey the same amount of air into the chamber but the way in which it is done is quite different.

In the first case the higher pressure air in the chamber will initially flow back into the compressor cylinder until pressures are equal and then it will be driven out again along with the new charge as the piston approaches the top of the stroke. Clearly unnecessary work is involved in this rather turbulent process but a further disadvantage is that the full pressure from the chamber is acting against the piston throughout the up stroke.

In the second case no such back-flow from the chamber occurs and the pressure acting against the piston rises gradually as the up stroke proceeds and only reaches that of the chamber towards the end of the stroke, at which point the valve opens allowing the charge to be expelled into the chamber. It must be obvious that this involves considerably less pumping work and can be carried out with less power.

In fact the excess power required by the first device is converted into heat which is added to the air transferred to the chamber. So this device not only consumes more power for the same job but it also heats up the air more as it does so. Hardly ideal for a detonation prone internal combustion engine - yet that is more or less how the Roots blower works, with adiabatic efficiency of barely 60%.

There are a great many examples of true compressors analogous to our second hypothetical device but the most viable for use as an engine driven supercharger is the screw compressor devised in the 1930s by a noted Swedish engineer called Lysholm. It has two helical rotors, male and female, which intermesh very closely without ever making contact. The helix action is of a continuous movement from the entry port towards a closed face adjacent to which is the delivery port. Air is drawn in normally at the open end of the rotors and is trapped as the rotors mesh together, gradually compressed between the rotor lobes and the closed end face as it is propelled along, then expelled from the delivery port at the required pressure. An important point is that the area of the rotor lobes acting on the charge diminishes as compression takes place therefore the power requirement remains more or less constant throughout the process. This is a significant advantage over our hypothetical piston compressor where increasing effort is required to drive the piston against the rising pressure. Of course the Roots device fares badly in this respect having the entire lobe area exposed to the higher pressure as delivery takes place.

Adiabatic efficiency of a screw compressor can be in the region of 75 - 80% and the delivery pressure can be matched to the engine by the drive ratio and delivery port geometry.

This efficiency gain compared to an equivalent roots device has been found to correspond to a reduction of air delivery temperature of 30-40 C and 25-30% less power consumption over a range of test conditions.

Since prewar days the screw compressor has been waiting in the wings threatening to make a grand entrance but the main problem for the cost-conscious motor industry has always been the relatively high cost of manufacturing the precision rotors. That has not stopped the type being widely adopted as a highly efficient industrial compressor. Hopefully, with enlightenment maybe the price will become unimportant in the same way that the complication of multi-valve cylinder heads has been rendered unimportant by the clear advantages. In any event, once an innovation is established, volume production always seems to bring the price to an acceptable level.

This is perhaps a good point to dispel a widely held belief that positively driven superchargers like the Roots, or the superior screw compressor, deliver air at constant pressure over the entire speed range. They do not.

Consider the case of a supercharged road engine with a wide torque spread and developing peak power around 5500 r.p.m. Starting at zero r.p.m. there cannot be any boost at all but as the engine speed rises so will the boost pressure until a speed is reached where any leakage and valve overlap blow-through will become insignificant. From that point on, maybe around 2000 r.p.m., the boost pressure will remain more or less constant as long as the flow capacity of the supercharger and the engine are well matched. Even then the system will be subject to harmonic effects which will have more influence on the flow capacity of the engine than that of the supercharger so the boost pressure will tend to rise or fall accordingly. In many after-market applications the engine and its exhaust system will not have sufficient spare capacity to handle the increased flow as the speed rises so perhaps around 4500 r.p.m. the boost pressure will start to rise, only slightly at first but becoming steeper, as the breathing limitations of the engine system are reached. In fact, although the boost pressure will be rising torque will now be falling off, gently at first but ever more sharply as the point of maximum power is exceeded. Going much beyond this speed is pointless because the boost pressure, air delivery temperature and power losses will all be rising savagely. Now perhaps the problem for the positively driven centrifugal compressor becomes glaringly obvious, doomed as it is to reach its best just as the engine reaches its limitations.

Theoretical Supercharging.

Whilst efficient supercharging certainly generates impressive performance there is a minor drawback with regard to thermal efficiency. In most engine systems the compression process is balanced by a similar ratio of expansion after combustion has taken place, during which the heat energy is converted into work on the piston.

Although it is common to talk of compression ratio, it is in fact the expansion ratio that is important for extracting work from the engine cycle and the simple supercharged engine can be a little disadvantaged in this respect. The problem is that if the supercharger delivers air at, for example, twice atmospheric pressure, which the engine then compresses in the normal way, then the effective compression ratio will be double the expansion ratio. Consequently a lot of heat energy will remain in the exhaust gas, subjecting the exhaust valves to higher temperatures with the potential to promote pre-ignition. The turbocharged engine is slightly better off in this respect because the expansion process continues via the turbine but the exhaust valves will still have to withstand high temperature gases. The supercharged aircraft engine had another way of making use of this unspent energy - ejector exhausts which added forward thrust. This was why companies like Rolls Royce were never keen to embrace the turbocharger even though it has significant advantages for high altitude flight. They knew that the gains in shaft horsepower from turbo-charging came at the expense of thrust from the exhaust, which they had already harnessed very successfully, and which was more significant at high speeds.

Of course, exhaust thrust has little relevance for road cars but fortunately the solution to the efficiency question is simple - just alter the valve timing so the inlet valve closes later by about 20 degrees or so. The compression process then becomes more equally shared between the supercharger and the piston so the compression / expansion balance is restored. This arrangement has been referred to as the 'Miller Cycle' after having been first proposed by an engineer called Miller back in about 1947. Without wishing to take anything away from Mr Miller, the idea of retarding the inlet cam by 20 degrees hardly justifies equating his name with Otto or Diesel, but he certainly had the right idea.

There is an often-overlooked advantage which supercharging can provide - preheating of the air charge in off-boost conditions to obtain significant emission and economy benefits during warm up and cruise. It is fortuitous that this takes place automatically because the losses from pumping against a vacuum appear as heat in a smaller volume of air which therefore becomes much hotter. Even a screw compressor can deliver air at around 150 C when off-boost.

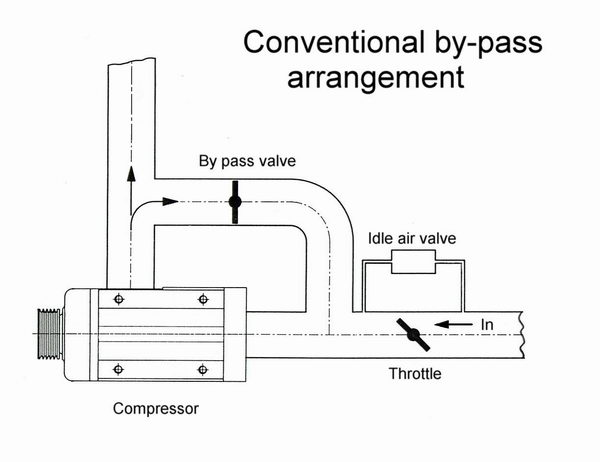

However, the effect does need to be controlled by some sort of by-pass or the pumping losses within the supercharger can outweigh the gains. Another drawback is that when the throttle is suddenly opened after a short period at light throttle the boosted charge is initially heated up as it extracts the latent heat that has built up in the system. This can give rise to a brief period of detonation - usually harmless but still undesirable. The same effect explains why supercharged engines often require minimal temporary fuel enrichment as the throttle is opened.

For highly boosted engines it can be better, not only to employ a bypass system, but also to place the throttle after the supercharger so there is no heat build up off-boost. A throttled supercharger on a racing engine, in the light load, high revving, condition during the seconds before the start of a race, can heat up nearly to the point of seizure, so as the car gets off the line both the blower and the engine (as the excess heat dissipates into the system) are under extreme stresses that do not apply at other times. Reliability is much improved with a bypass and throttling after the supercharger.

Practical Supercharging.

First let us briefly consider the airflow tract. It seems to be a common belief that when an engine is supercharged there is no need for careful attention to equalising flow through the individual manifold tracts because the air is being blown through the system and will therefore find its own way. That this is a fallacy is easy to demonstrate. If balancing of flow is less necessary when the charge density is increased by supercharging then it must follow that at light throttle with low density, flow balance becomes more critical. Experience shows this to be most certainly not the case.

It seems even now to be a little recognised fact that adding just a proportion of the fuel before the supercharger is a very effective method of lowering charge temperature by evaporation during compression, as well as being a good method of mixture preparation. There is an efficiency gain here which is not immediately obvious. Cooling the charge as it is compressed is of more benefit than any form of cooling after the event (by an inter-cooler for instance, although further charge-cooling may still be beneficial) because the work consumed by the compressor will be reduced. Water or water/methanol injection can be used for the same purpose. This important advantage is denied to the Roots device because of its lack of internal compression. Stanley Hooker estimated that adding fuel ahead of the supercharger dropped the air temperature by 25 degrees C on the Merlin, enabling it to consistently outperform the larger and supposedly more advanced German engines with direct fuel injection into the cylinders. Fuel has to be added anyway so why not add it where it will do most good?

There is still another fallacy that needs to be dispelled. The idea that a supercharged engine must have a low compression ratio. Lower perhaps, but not by much. The old idea that compression must be reduced dramatically merely produces an engine that is unresponsive and thirsty in the off-boost condition. A much better approach is to use the highest practical compression ratio, then control the delivery temperature and ignition timing when on boost. In fact the high pressures and greater charge turbulence speed up the combustion process anyway so it all comes back to the air delivery temperature being the critical factor.

The Future.

Of course the racing fraternity are never slow to use something that gives an advantage and nowhere in motor sport are superchargers used to such good effect as in Dragsters. In recent years the screw compressor so dominated the upper echelons of Drag racing that its users had to accept a performance handicap so that the traditional GMC Roots blower could remain competitive. Incredibly, in this sport of spectacularly powerful engines, the power needed to drive a Roots blower is over 300 b.h.p. more than that required to drive the equivalent screw compressor, which incidentally also displays much better reliability. Superiority indeed! How long will it be before this kind of supercharger dominates the high performance car market?

So finally, what difference would it make to the Jaguar XJR V8 if it had a screw compressor instead of a Roots blower, had more effective intercooling and injected some of the fuel on boost ahead of the compressor. Quite a few people have tried changing the drive pulley ratio to speed up the blower but have found that the results are disappointing. Certainly torque goes up as one might expect but the blower efficiency just gets worse with rising speed so it becomes a struggle to get beyond about 410 - 420 b.h.p.

A clue to the potential of a screw compressor is provided by the application of one (an Opcon Autorotor) to an Aston Martin DB7 engine - in standard form basically a Jaguar 3.2 AJ6 engine with a Roots blower. The standard DB7 produces 335 b.h.p. but the Opcon version delivers nearly 100 b.h.p. more, aided admittedly by some exhaust improvements but with the engine itself remaining just the same.

For the Jaguar 4 litre V8 we can estimate that torque would rise from 387 lbs. to about 440-450 lbs. and power would go up from 370 b.h.p. to somewhere around 475 b.h.p. Such a project is already in progress!

In the years to come it is likely that political pressure will force high performance cars to be extremely fuel efficient if they are to survive. However, small supercharged engines will have the advantage of faster warm up and therefore reduced exhaust emissions for a given level of performance. Watch out for the screw compressor - its day is not far off!

Roger Bywater, AJ6 Engineering.

Dennis Priddle, AJ6 Superchargers.

Email aj6engineering@ntlworld.com, Tel/Fax:- 0044 (0)1625 573556