|

It may cause some surprise to learn that the first Jaguar to run using L

Jetronic was not an XJ6 but an XJ12 series 2 saloon. In fact this

particular prototype was put together in early 1974 using 2 separate L

systems - one to each cylinder bank. Whilst I cannot now be certain on this

point I rather think it had Lambda sensors and must therefore have been one

of the earliest applications of this technology. Certainly the car was used

over a number of years for emission development work.

In the UK we tend to identify the EFI 4.2 engine with the Series 3 saloon

but it actually appeared a year earlier in Series 2 cars for the US market

where the carburetter engines could no longer comply with emission

legislation.

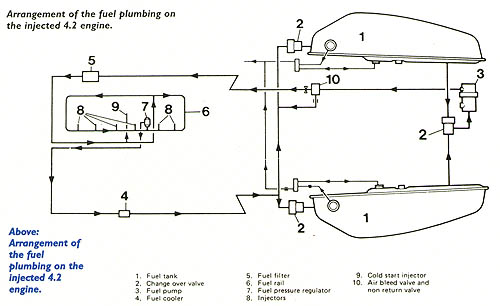

FUEL PLUMBING & HARDWARE

The general arrangements of the pipe work and various components around the

engine are shown in the accompanying diagrams and are well described in

various manuals so there is not much point in dwelling on the subject

further. In the same way the major components of the induction tract do not

need detailed description here. Instead the aim is to deal with topics

which are less well understood.

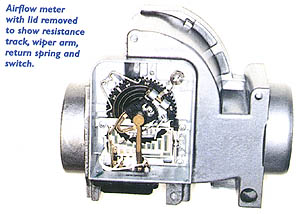

THE AIRFLOW METER

The key instrument in L Jetronic is undoubtedly the airflow meter (see

photo), composed essentially of a graduated air passage containing a hinged

flap which deflects against a spring according to the flow of air through

the passage. The flap is mounted on a spindle and directly controls the

position of a sliding contact along a resistive track. Although the track

itself incorporates a complex array of laser trimmed resistors the

principle is very simple: just a potentiometer producing an output voltage

according to the deflection of the flap (see diagram).

|

Like most things of course the satisfactory operation of the airflow meter

involves some sophistication in its design features. For instance a simple

flap pivoting in the air-stream would be overly-sensitive to any resonant

pulses in the induction tract and any spit-back from the engine would be

likely to blast it back violently against the incoming flow to the limit of

its travel. To resolve these problems a second flap was added at 90 degrees

to the first, pivoting within a damping chamber. The idea was that any

pulse or spit-back striking the two flaps would be largely balanced either

side of the pivot point and any sudden movements would be resisted by the

damping chamber. This worked quite well for pulse absorption but the much

stronger shock wave generated by a spit-back could still blast the flap

onto its closed stop with such severity that the spindle bearings could be

knocked out of alignment causing the flap to jam. Originally a spring

loaded relief valve was built into the flap to relieve such pressure waves

but did not react quickly enough so was superseded by the simple expedient

of a small rubber buffer at the entrance to the air passage.

|