Some History.

The Jaguar XK engine is rightly regarded as a classic design that was well in advance of most others at the time of its introduction. Its remarkable qualities were proven in competition during the 1950s and it was good enough to remain in continuous production for very nearly 40 years, although it was showing its age towards the end, as was the machinery on which it was made. It even managed to survive into the era of electronic fuel injection, which could hardly have been foreseen by the original design team. This final version of the 4.2 XK, with its big valve head and Bosch L Jetronic fuel injection, gave the best all-round performance of all production XKs - even the famous triple SU engine would have been hardly more powerful and certainly less fuel efficient, had it been subjected to the same DIN test. With lowered compression, Lambda feedback and a three way catalyst the XK managed to comply with tough US emission standards and carried the Series 3 XJ6 along until the XJ40 arrived. In fairness the elderly hemispherical combustion chamber was not ideal for the age of emissions legislation and in this form the idle qualities and performance were getting rather marginal.

Proposals for updated cylinder heads go back a long way. A fresh cylinder head that saw plenty of action was the well known 35/40 head in which the exhaust valves were angled outwards by 5 degrees to make room for bigger inlet valves. These heads were used on racing engines from 1955 in D types through to the lightweight E types of the early 1960s. With inlet valves of up to 2.1 inch diameter these were quite powerful engines but their potential was eventually limited by mechanical and combustion considerations rather more than flow capacity. 1959 saw the introduction of what became known as the straight port head, as opposed to the original design with slightly curved inlet ports, for extra power in the more sporting Jaguars. In later years the straight port head became the standard production item.

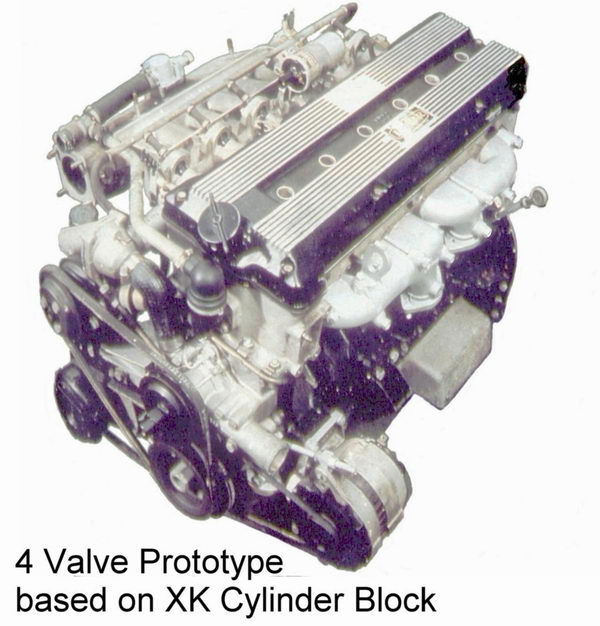

The conflict between the need for more valve area and having a compact combustion chamber was something that was becoming apparent to everyone involved with high performance engines in the early 1960s and was prompting serious thought about the 4 valve layout.

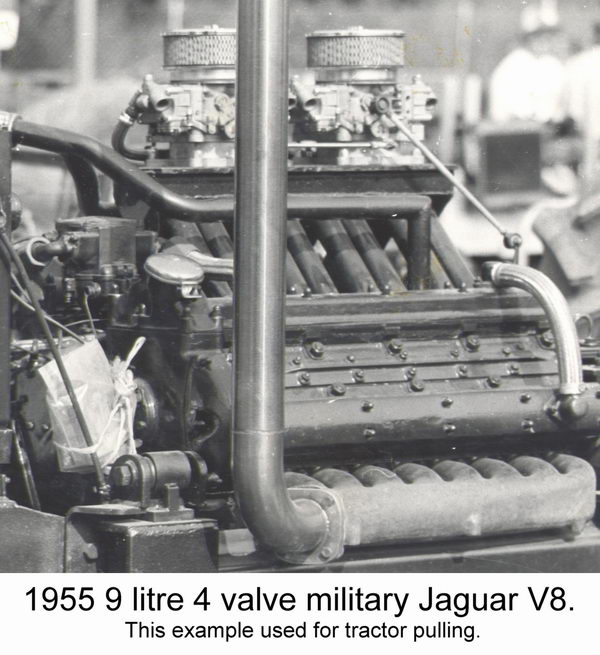

Jaguar already had some four valve experience from designing a military 9 litre V8, with obvious visual similarities to the XK, and which had the pairs of valves inclined at somewhere around 90 degrees apart. Also an experimental four valve racing version of the XK with desmodromic (i.e. spring-less with positive valve closure) valve gear was built during the 1950s. It is likely that it would have followed the wide valve angle of the military V8 so the combustion chamber would still have been compromised.

It is probable that Harry Weslake, who had contributed so much to head and port design for Jaguar and Coventry Climax, amongst others, was the first to produce what has now become the norm - the narrow angle 4 valve configuration - combining good flow, generating horizontal swirl within a compact combustion chamber, and fired from a central spark plug. Keith Duckworth states that he arrived at the layout quite independently in the process of creating the outstanding DFV racing V8. No doubt that is true, but Weslake was running a twin cylinder four valve research engine with 32 degrees (same as the DFV) between the valves in 1965, from which evolved the Eagle Weslake V12 GP engine, which made its track debut about 6 months before the DFV.

It is worth pointing out that Harry Weslake had a lot of influence in the design of the original XK cylinder head and was instigator of the original curved inlet port to promote swirl. He also played a part in the development of the 35/40 racing head, but was never happy about the adoption of the straight port head for production engines, believing that the inlet port needed more curvature rather than less to aid part load efficiency. He was probably right, charge movement at full throttle is hardly ever a problem, but at part throttle a bit of a stir is often needed to 'get the fire going'.

Driven by demands on emissions and economy Jaguar built a small number of four valve XK engines in the mid-to-late 1970s. From memory these had updated versions of the XK block, still in cast iron but with open deck construction rather like the V12. They had a bore and stroke of 90 mm x 100 mm giving the familiar size of 3.8 litres and introduced the idea of the head bolts passing through the cam bearings, a feature of the AJ6 engine. Really there was not a lot of point in soldiering on with makeshift solutions when what was really need was a completely new engine, but this embryonic head design did form the basis of what eventually became the AJ6 engine.

Nevertheless the adoption of EFI extended the XK's life for another 8 years or so and opened up new development paths by which the performance of the 4.2 production engine could be significantly improved at relatively modest cost. For those who are interested, there are two of our articles, commissioned for Jaguar World magazine, linked to this site detailing the technical history of the XK engine and the workings of the L Jetronic EFI system.

Performance Enhancements.

We have found the following to be good ways of improving the performance of the EFI 4.2 engine:-

1: The airflow meter, with its spring loaded sensing flap, is an obvious restriction to flow, amounting to about 12% loss of power according to our own measurements. Ideally from a performance point of view one would dispense with it, but to do so at reasonable cost is not easy. Fortunately, by lightening the load of the spring resisting the movement of the flap the power loss can be reduced by about half, yet all the advantages of the system remain. The trouble then is that the ECU receives a signal indicating that far too much fuel is required so it must be re-calibrated to work with the new signal. Fortunately we have the necessary specialist equipment to measure both airflow and injector pulses in controlled conditions so it was not too difficult for us to arrive at specifications of airflow meter and ECU calibration that could be interchanged with the original items as a matched pair to fuel the engine accurately yet permit higher airflow. We also add an overall trim adjustment to the ECU to take into account the effects of aging of individual cars. With the addition of a high efficiency air filter and supplementary air intake this became our PLUS FLOW CONVERSION, to liven up any 4.2 XJ6 EFI saloon by approximately 22 b.h.p.

2: The design of the 4.2 EFI inlet manifold owes more to expediency than theoretical perfection, emissions legislation being the prime consideration, and the individual induction tracts are much shorter than the ideal, indeed more so than other Jaguar engines. One only has to look back at the length of the tracts used on the Lucas injected, wide angle head of the D type racers to confirm that this is so.

Fortunately the plenum chamber is large enough to permit long bell-mouthed extensions to be added to the individual tracts - but it must be cut open, the tracts machined, extensions fastened in place and the whole thing welded back together as our HIGH TORQUE INLET MANIFOLD. The photograph shows the extensions in place ready for the plenum to be welded back to restore the original appearance.

Adding this to the PLUS FLOW CONVERSION creates our PLUS TORQUE CONVERSION which lifts maximum torque from 236 lb / ft to within a whisker of 270 lb / ft whilst adding another 10 b.h.p. for a total gain of 32 b.h.p.

3: As with other Jaguars the design of the exhaust system is dominated by the need for refinement but many people think that the system on the 4.2 Jaguar is a little too quiet for a car with high performance pretensions. Fortunately it is quite possible to obtain a reasonable increase in performance allied to a pleasing exhaust note without becoming antisocial. The simplest way of doing this is to replace the first silencer boxes with our SILENCER SUBSTITUTE PIPES for a gain of about 15 b.h.p. These can also be used on most catalyst cars and are pre-formed to join into the existing system.

A standard size exhaust with all straight through silencers is available for those whose requirement is for a HIGH QUALITY STAINLESS SYSTEM. Also available is a LARGE BORE SYSTEM with all straight through silencers which obviously removes most of the restriction from the system but in reality only gives about 5-10 b.h.p. more than the Silencer Substitute Pipes so is only really worth thinking about if the complete system is in need of renewal.

For best road performance a cost effective solution is our recently introduced TT EXTRACTOR SYSTEM (Twin Tube) which replaces the forward section with long pipes from each group of three cylinders, merging at the back of the transmission then dividing again in the usual fashion ahead of the rear axle assembly. Connecting to a standard rear section this boosts mid-range torque by approximately 9%. The exhaust note has a sharper tone than standard but is by no means antisocial. For those who seek top end power it can be used with a large bore rear section for a gain of about 30 b.h.p.

RACING OPTIONS.

Some of our performance conversions for the 4.2 engine are available in slightly different forms for racing. The Racing High Torque inlet manifold has shorter internal bell-mouths, and the Racing TT Exhaust has shorter pipe lengths before the merge point. The effectiveness is thereby pushed higher up the speed range where it is more useful on the track.