As the name suggests the core business of our associate AJ6 Superchargers involves the design and production of supercharger kits for engines and, of course, the sale of high efficiency superchargers, all backed up with an exceptional level of expertise. Before delving into that it is worth looking briefly at the contribution AJ6 Superchargers makes to our products for Jaguars.

Dennis Priddle, a well known name from the world of Dragster racing, 'IS' AJ6 Superchargers and uses his considerable engineering skills to produce the special high torque manifolds for V12, AJ6 and XK engines. This work entails precision machining and aluminium welding to a very high standard such that it is hard to distinguish the modified parts from standard just by looking at the exterior. Peering inside tells the real story of how extra bell-mouths have been added onto the individual tracts - all rather reminiscent of the old "ship in the bottle". There are a number of photographs of this work in the appropriate engine sections on this site.

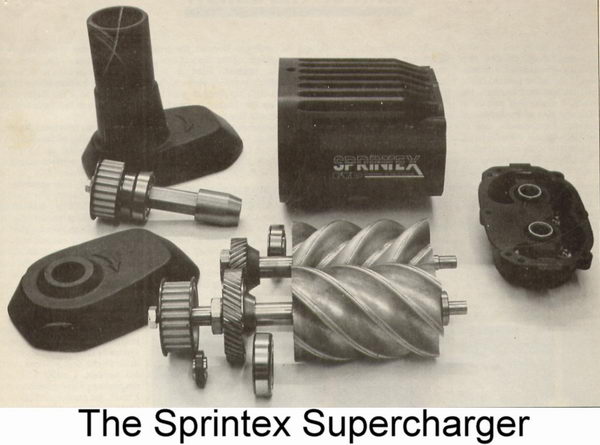

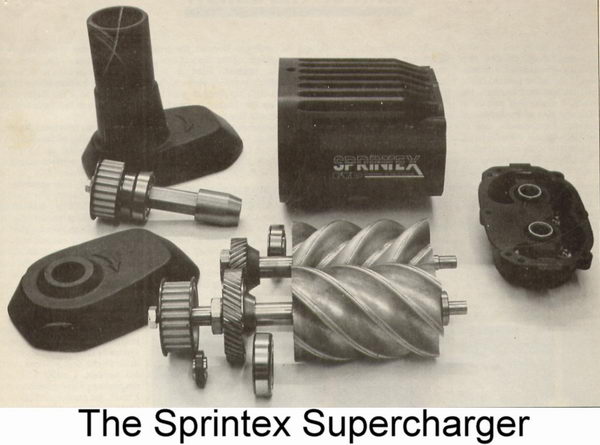

Returning to the main subject, AJ6 Superchargers evolved from an earlier company that manufactured the highly regarded Sprintex supercharger. Now it is the agent for the Swedish OPCON AUTOROTOR superchargers - a range of high efficiency screw compressors, of more modern design than the Sprintex, suitable for engine powers up to 1200 b.h.p. The efficiency of these devices (meaning the boost available for a given power absorption) is considerably better than the Eaton roots blower which owes much of its popularity to low price and ready availability.

The act of compressing air must always add heat but the way to minimise this is to raise the efficiency of the process. To put numbers on it, the Eaton blower used on the Jaguar V8 operating at 700 c.f.m and 1 bar boost consumes about 84 b.h.p. and delivers air at 139 C. A comparable screw compressor at the same airflow and boost pressure consumes 59 b.h.p. and delivers air at 98 C.

Substitution of a screw compressor for a roots blower can therefore be expected to increase performance by a considerable margin. Replacing the Eaton supercharger on an Aston Martin DB7 (based on the 3.2 Jaguar AJ6 engine) with an Opcon unit boosting at nominally 0.8 bar (12 p.s.i.) along with revisions to the exhaust system and engine management produced 430 b.h.p. at 7000 r.p.m. It produced 300 lbf of torque at 2000 r.p.m. and 390 lbf of torque was available from 3500 to 6000 r.p.m. So for the same boost this 3.2 engine with standard camshafts and standard sized valves outperformed Jaguar's supercharged 4 litre XJR V8! What makes the difference is the lower air delivery temperature and reduced power absorption of the more efficient supercharger.

Anyone wishing to know more about the technicalities of supercharger efficiency and why one type is superior to another might care to look at the article linked to this page which provides a detailed explanation of the technology.

Dennis Priddle learnt about supercharging in the hotbed of Top Fuel Dragster racing where there is no margin for error. Getting it wrong usually means either coming home second or shoveling up the remains of a very expensive engine. Engines that swallow nitromethane fuel (see footnote) at a rate of about 2 gallons per second and produce around 7000 b.h.p. have more affinity with an unexploded bomb than with most other forms of racing engine. Detonation takes on a whole new meaning here.

Although the dragster engine is an extreme example the rule about supercharging is no different from any other engine. The charge temperature needs to be as low as possible which means an efficient compressor correctly matched to the engine is the best starting point. Every single degree of heat added to the charge by the supercharger represents a double deficit in that less power will be produced and more of what is produced will be wasted. Hot air provokes detonation so the ignition timing must be retarded to keep the engine safe. Intercooling certainly helps and will be necessary for any more than moderate boost, but is really only a way of getting rid of heat that ideally shouldn't have been there in the first place. Of course at higher levels of boost intercooling becomes necessary to remove the heat produced by even the most efficient supercharger.

In times past it was usual for supercharged engines to have a much reduced compression ratio to avoid detonation at full throttle. Such engines generally gained a reputation for heavy fuel consumption and poor response. These days supercharged engines run at compression ratios that would have been considered normal for naturally aspirated engines a few years ago and detonation is avoided by electronic control of ignition timing. Fuel efficiency and responsiveness in off-boost operation is therefore much improved. As an example the naturally aspirated Jaguar V12 of the 1970s ran at 9:1 compression ratio, produced 285 b.h.p. and required 97 octane fuel, yet the Jaguar XJR-V8 runs at the same compression ratio with 0.8 bar (12 p.s.i.) boost and needs only 95 octane fuel to produce nearly 100 b.h.p. more from 1.3 litres less capacity. That's progress.

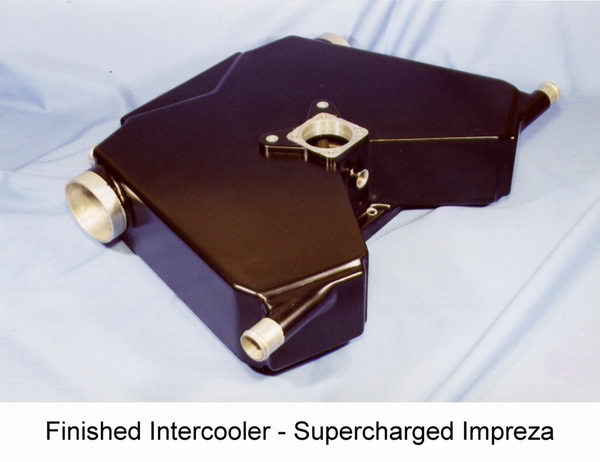

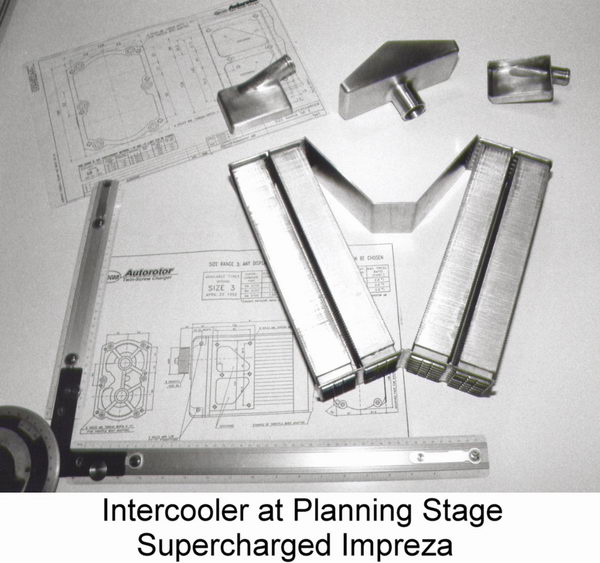

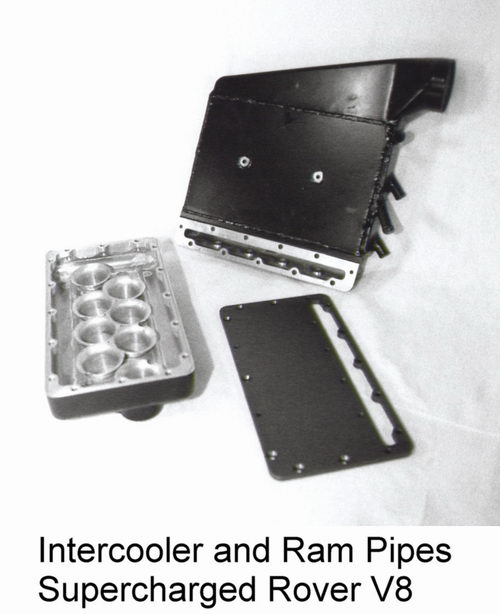

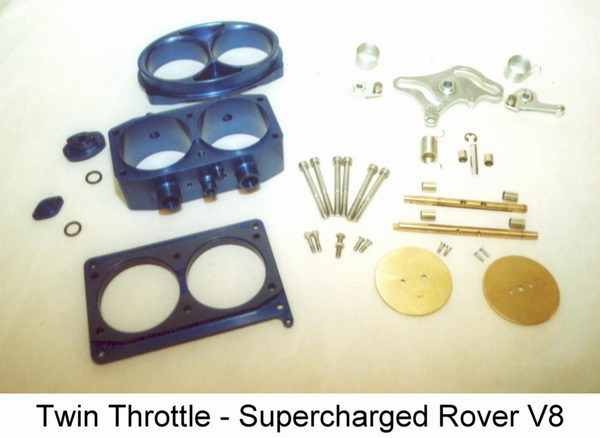

Dennis Priddles's forte is the design and manufacture of specialist engine components. A lot of people know how to use modern NC machine tools but not so many also understand engines. With expertise in both fields AJ6 Superchargers can undertake projects and prototype work to standards that only the best can match using an in-house 3D cadcam system. Past projects have included prototype supercharged engines for major motor manufacturers as well as special purpose competition engines. Some photographs follow that clearly illustrate the high standards which prevail at AJ6 Superchargers. Prices and quotations are available on request.

Racing Fuels - Gasoline, Alcohol and Nitromethane.

The key to high power fuels is the specific energy that is available during combustion. This is not something that should be confused with the heating or calorific value (the heat generated by burning a test sample). For instance normal gasoline has a typical heating value of about 43 whereas for methanol the figure is only around 19.9. Taken at face value methanol is therefore obviously a very poor fuel so there must be other reasons why it can produce more power than gasoline from an engine.

The answer is that the specific energy, not the heat value, determines the potential for a fuel to generate power. If more fuel can be burnt effectively with a given amount of air then more power will result, but this should not be taken as meaning that just adding more fuel necessarily always means more power. The stoichiometric (chemically correct) air/fuel (A/F) ratio for gasoline is approximately 14.7:1 but best power is achieved at richer A/F ratios around 12-13:1. This is partly because of the charge cooling effect of the extra fuel and also because the presence of slight excess fuel means all the air in the charge will be burnt. Further enrichment beyond this point will cause power to fall. If gasoline were treated to contain oxygen then the stoichiometric A/F ratio and that for best power would reduce because the fuel would then need less air to form a combustible charge. It would therefore then be possible to burn more fuel and the specific energy of the charge would increase accordingly. Oxygenated compounds such as MTBE (18.2% O2 by weight) are sometimes blended into racing gasoline for this purpose as well as for the increased resistance to detonation. It should be remembered that air contains only 23% oxygen by weight so quite modest additions of oxygenates to the fuel can make a measurable difference.

Whilst it is not actually a fuel, Nitrous Oxide is relevant in this respect having an oxygen content of 36% so its addition permits more fuel to be burnt. Apparently adding 5% Nitrous Oxide to a charge with appropriate fueling could produce up to 9% power gain.

Alcohol, usually in the form of Methanol, is an oxygenated compound (50% O2 by weight) which has a stoichiometric A/F ratio of 6.45:1 and an octane rating in excess of 115 RON permitting use of higher compression ratios. Maximum power is obtainable at the very rich A/F ratio of around 4:1 so the usable specific energy (3 x 19.9 = 59.7) is much higher than gasoline, although of course fuel consumption will be dramatically increased.

Still more extreme is Nitromethane. Most people know that "nitro" is some sort of "super-fuel" but not so many know why, so perhaps a brief explanation is called for. It is an oxygen bearing compound with an energy content (specific energy) 2.3 times that of gasoline. Not only that but its stoichiometric A/F ratio is 1.7:1. What this means is that a charge of nitromethane mixed with air in the perfect ratio contains about 20 times as much energy as a comparable gasoline charge. Best power is at richer A/F ratios than stoichiometric, as with gasoline and methanol, so a nitro burning dragster engine might run at an A/F ratio of around 1:1. Detonation resistance is not particularly good but is offset by the extremely rich A/F ratios.

Nitromethane can even be used as what scientists call a "monopropellant" - which means it will combust without need of any air at all but for practical reasons it is usually blended with about 10% methanol for use at a unity A/F ratio as stated. A useful side effect of introducing liquid fuel in these vast quantities is the cooling effect on the engine internally through evaporation - but just one misfire can mean a hydraulic lock and a wrecked engine in an instant.

Finally there is a really wild fuel additive called Hydrazine (N2H4) which can be blended with methanol or nitromethane. Adding just 1% by volume gives a significant power increase BUT it is extremely unstable and after a number of what might be called 'violent incidents' had to be banned from use.

Contact us at:-

AJ6 Superchargers

Halves Lane

East Coker

Yeovil

BA22 9JJ

UK

Tel/Fax:-0044 (0)1935 862260

email:- prid@alien9988.freeserve.co.uk"

or via:-

AJ6 Engineering